Smart Home &

Home Appliances

A new generation of devices is conquering the living space. The trend toward closed surfaces is fundamentally changing designs and components. At KURZ, you can experience what ultra-thin film technology, high-quality finishes, new materials, and integrated sensor technology make possible: New products are becoming more individualized, yet at the same time more robust, durable, long-lasting, and sustainable. As a manufacturer, you can benefit from a continuously optimized value chain.

Front panel with hidden-til-lit effect

This bezel stands out thanks to its elegant dark design. Only when the display is touched does the intuitive HMI user interface appear in the form of a high-resolution LCD display or sensor solutions with LED backlighting. The advantage of this hidden-til-lit design is that the buttons can be freely assigned. Decoration is carried out in a single step using the economical IMD process, in which the bezel is injection molded and decorated at the same time.

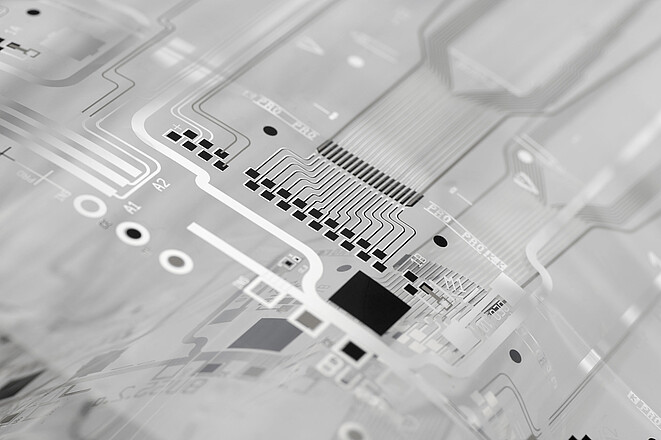

Sensor technology for LCD displays and solutions with LED backlighting

The human-machine interface is based on sensor technology developed by KURZ subsidiary PolyIC. The cost-efficient multi-touch sensor solution for LCD displays enables homogeneous, seamless display integration and the programming of a wide variety of operating modes. The structure for the PolyTC® VarioSym sensor technology with uniform LED backlighting features a touch sensor, integrated diffuser, and laser-engravable decorative layer. This eliminates the need for additional components to ensure homogeneous illumination of characters and symbols. These can be customized at the end of the process chain, as can the languages. Advantages: few integration steps and a very delicate display of symbols and control elements.

Real metallization

Matte, glossy, brushed, backlit – with full-surface or partial metallization using hot stamping, you have THE sustainable alternative to electroplating at your disposal. The finishing, which is also possible on a partial basis, uses wafer-thin real metal and is extremely economical, recyclable, and suitable for recycled materials, even for small series.

Intelligent interface heroes with IMD UNIFY

Style upgrade for household appliances with IMD UNIFY. The basic decoration is efficiently produced in series and can be customized retrospectively via digital printing: ideal for special design editions, different language versions, logo variants, and more. An additional bonus for efficient use of resources: savings in buttons, switches, numerous transport routes, and work steps.

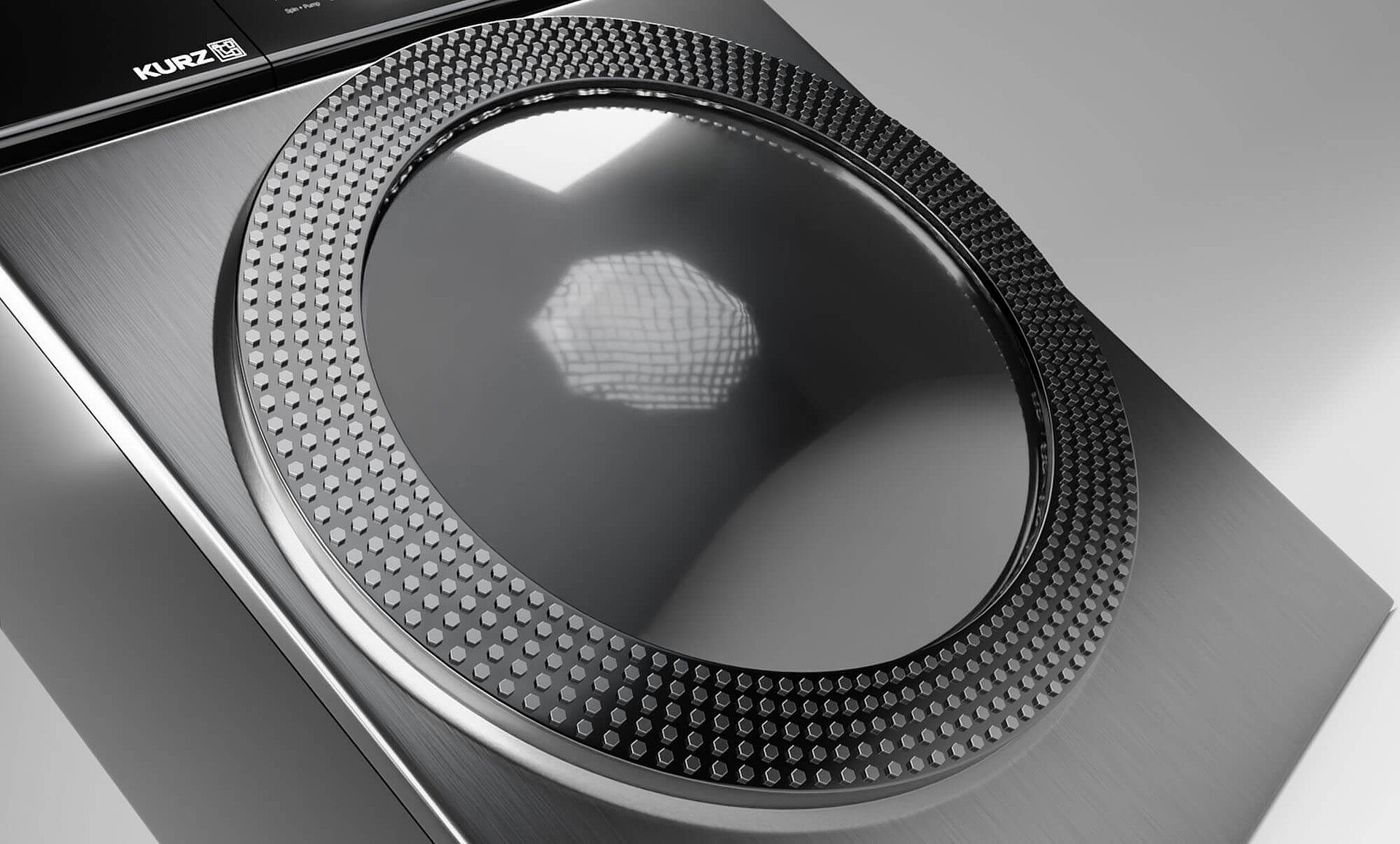

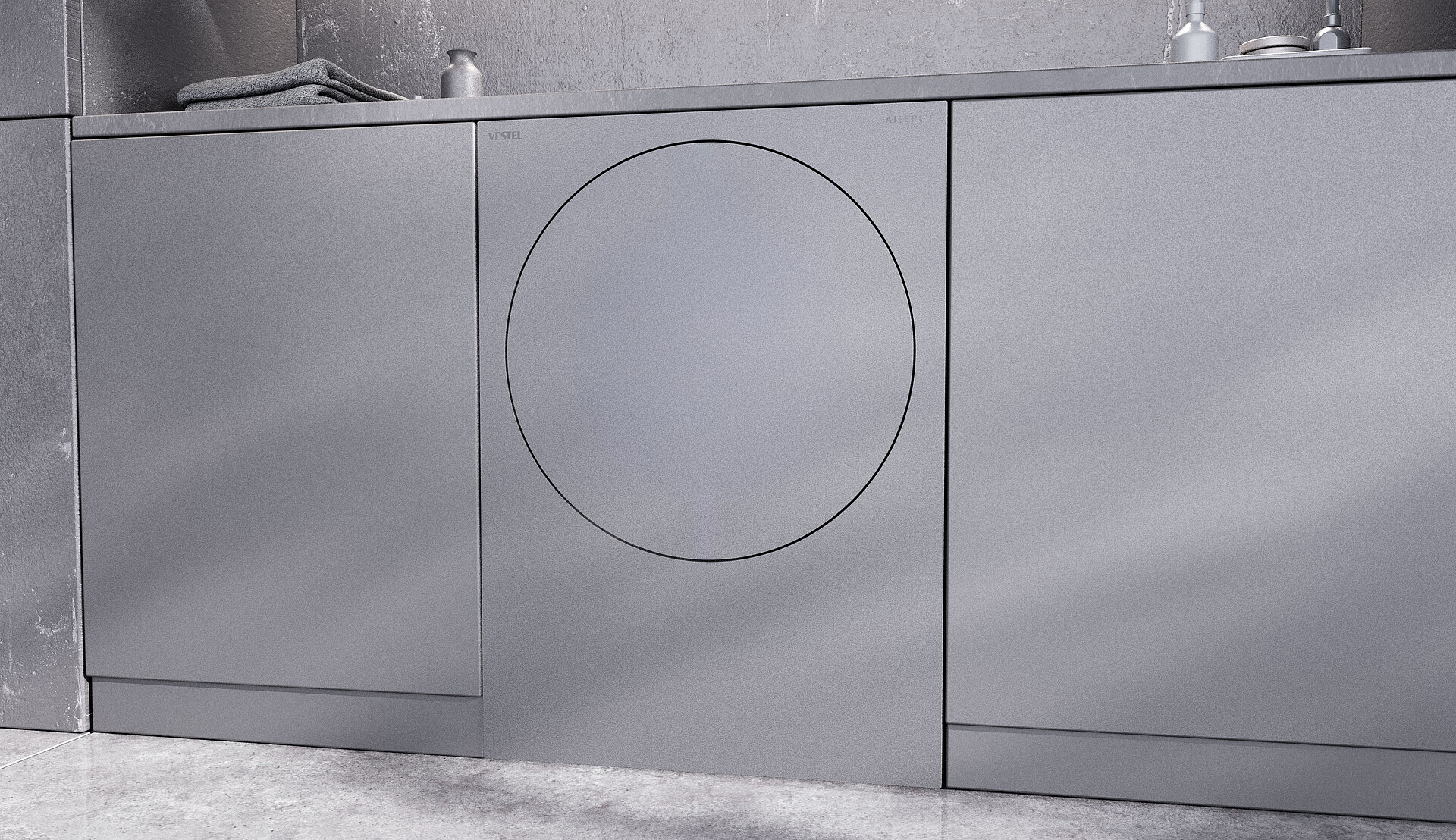

NEXT Washing Machine

In cooperation with leading Turkish manufacturer VESTEL, KURZ has developed a concept for futuristic product design with innovative surface technologies. The NEXT Washing Machine combines sophisticated aesthetics with intuitive operation and ecological responsibility.

Design and function: bold.

A rectangle. An oversized circle. Purist design can be that bold. Processes suitable for series production were used, such as Hot Stamping and In-Mold-Decoration (IMD). These highly efficient processes enable a quick response to market trends thanks to easily adaptable color and design options – for large series, limited editions, or completely customized individual devices.

Home, smart home

When switched off, the appliance impresses with its homogeneous surface and understated design. When switched on, it offers a special eye-catcher: the integrated touch display with hidden-til-lit surfaces, ambient lighting tailored to the washing program, and seamlessly integrated PolyTC® sensors for an intuitive user experience.

Monomaterial construction – up to 100% recyclable

Visually appealing, technically advanced, functional, and sustainable—the NEXT Washing Machine impresses across the board. Among other things, this is thanks to its highly efficient processes and monomaterial construction, which simplifies recycling.

Our partner

Fridge Interior Designs

The refrigerator becomes cool. Whether large-scale Hot Stamping on the rear wall or fine detail embossing on compartments or strips: in just one process step, the interior can be partially or completely refined—with completely new colors and metallized designs. Reduced components, recyclable monomaterials, and surface decorations ensure added sustainability.

Customized interior

Unusual lighting effects, backlit elements, or atmospheric ambient lighting? No problem with an integrated light mask. Customer-specific requirements for food safety standards in the food sector? Can be implemented without additional effort — as can the use of soft-touch elements or digitally visualized variants via augmented reality.

Our partners

Luxury Coffee Machine Concept

Sophisticated IMD and Hot Stamping decorations on glass and plastic surfaces — for example, in a gray marble look — give coffee machines a particularly high-quality appearance. Matte surfaces emphasize the monolithic character of modern appliances, while glossy designs add glamour. Contrasting decorations can be used to highlight individual functional elements such as the drip tray – here hot stamped in chrome. Equally easy to implement: brand-specific color schemes, logo placements, or tactile structures. All decors are durable, hygienic, and recyclable.

Coffee enjoyment – a question of technology

Front displays made of real glass with PolyTC® touch sensors and a hidden-til-lit effect promise premium visual and tactile enjoyment. The capacitive touch surfaces and backlit controls remain discreetly in the background and only appear when needed. Thanks to PolyTC® Colorful Pictures, high-resolution color images can be integrated into the control panel.