The challenge

The desire for innovative design solutions is moving into more and more product worlds, including the hygiene dispenser sector. To develop economical and sustainable solutions, manufacturing process and product must form a perfect "match". That's why manufacturers need innovative solution partners who think along the entire value chain and keep an eye on the specifications of the respective industries. How the balancing act between customer requirements, design, efficiency, innovation, and quality can be mastered has been proven by the partners LEONHARD KURZ and Kimberly-Clark Professional™ with their award-winning design of the ICON™ series.

The goal

In-Mold Decoration IMD is an outstanding process that allows immense design freedom while maintaining superior quality. For the new Kimberly-Clark Professional™ hygiene dispenser series, it was up to LEONHARD KURZ to develop a surface finish that would meet the high demands of the washroom environment: perfectly adherent designs with color stability, resistant to humidity and temperature, resistant to solvents, detergents and disinfectants. In addition, new design solutions for future series should be easy to implement, and the manufacturing process should be able to be integrated as seamlessly as possible into existing production lines. Another requirement in terms of sustainable processes: Even with recycled material, the decorations should meet the same high design and quality requirements.

The solution

IMD (In-Mold Decoration) is the process of choice for these requirements. Injection molding and decoration take place in a single step, reducing material consumption, energy, and CO2 emissions. For this purpose, foil feeding units from KURZ are installed on the injection molding machines. Their sensors align the register marks of the carrier material with the decorative IMD coating extremely precisely, ensuring constant application of the decoration to the injection-molded component.

For a perfect decoration result, the component geometry of the design panels still had to be adapted so that tool technology and product design were optimally matched. IMD decoration places certain requirements on components and molds, which LEONHARD KURZ, as a leading specialist in surface decoration, thinks about from the very first idea. ABS was used as the base material, but recycled material is also suitable for the new ICON™ series.

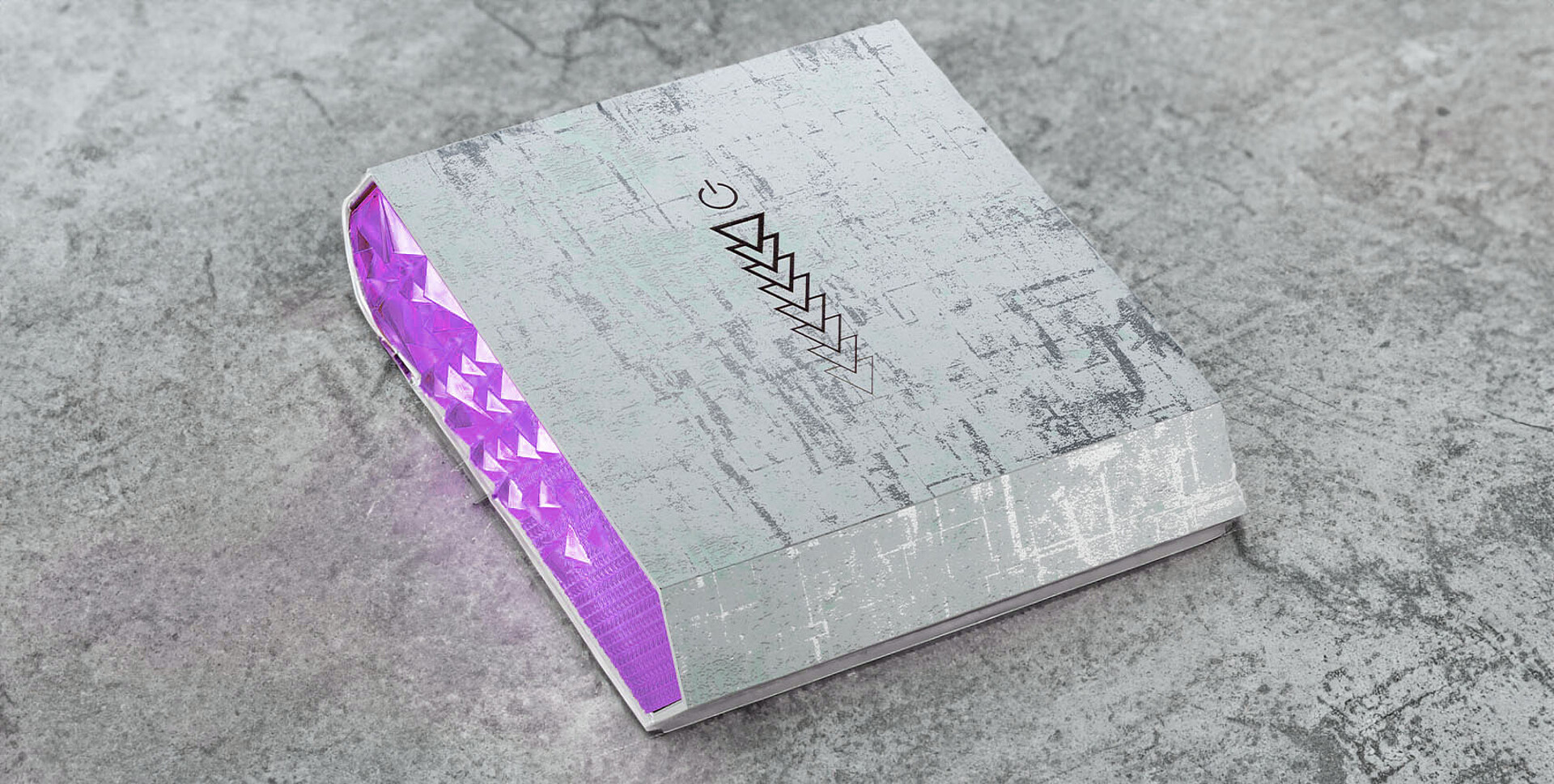

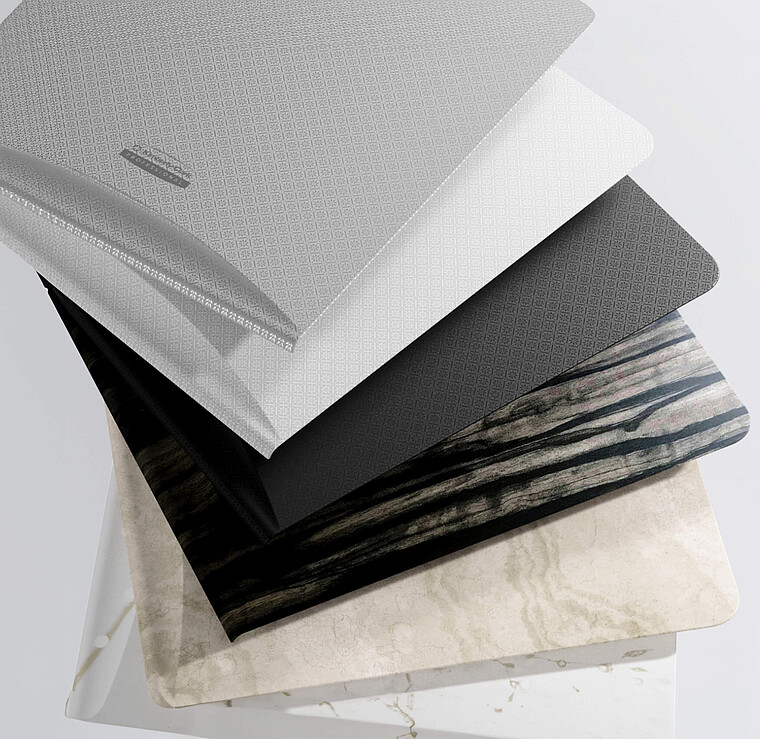

The coordination of the different designs was also carried out in close cooperation between the two partners. The new ICON™ range currently includes six interchangeable front panel designs in three natural looks (marble, cherry blossom, ebony grain) and three modern classics (geometric mosaic patterns in black, silver, and white). With the transparent antibacterial and antiviral protection KURZ BIOFENSE® AntiViral, surfaces can be hygienically protected in the long term, including against SARS-CoV-2 viruses. The application of KURZ BIOFENSE® can be integrated into the IMD process.

Why LEONHARD KURZ is your ideal technology partner

- Design for recycling: The decorations are recyclable and do not affect the recyclability of the components.

- Recyclates can also be used and can be finished to the same high quality as virgin material.

- The efficient IMD process saves material and energy and significantly reduces CO2 emissions.

- Extremely flexible design solutions set new trends.

- Limitless creations in terms of design, look, feel and backlighting are possible.

- Intelligent solutions and shy tech design can also be realized.

- Surface resistances can be customized.

- Suitable for both small and large series.

Conclusion

IMD is an extremely efficient and economical process that allows unlimited design variations. Special series can also be realized to the advantage of large-scale production. Close coordination along the entire value chain results in solutions that strengthen manufacturers' market position with their customers. In addition, IMD decorations have lower CO2 emissions and material and energy consumption than conventional processes. Due to the very successful implementation and market launch, further designs for the new Kimberly-Clark Professional™ ICON™ series are already being planned with LEONHARD KURZ.