KURZ Energy Technologies

Battery components

KURZ Energy Technologies

Battery components

Battery components from the EU

KURZ as a strategic partner for innovative coatings for battery cells and system components

Battery technologies - such as lithium-ion batteries - are indispensable in modern vehicles and electronic devices due to their high energy density and long service life. In order to strengthen the European economy, reduce greenhouse gas emissions and improve environmental standards, key production steps must take place in the EU. This is where KURZ comes into play with its Energy Technologies division: Our expertise in thin-film technology and central location in Europe make us an important strategic partner for high-performance coatings on battery cells and system components. And with our partnership with Jiangsu Horizon for coated separator films within the joint venture Horizon-Kurz New Material Technology GmbH – we are adding years of expertise in the Li-ion battery cell market.

How you benefit as a KURZ partner

- Battery cell components produced in the EU

- Sufficient capacities and security of supply

- Economical use of materials and resource-saving processes

- Extensive experience in the automotive sector

- Reliable development partner

- Combined expertise of Horizon and KURZ

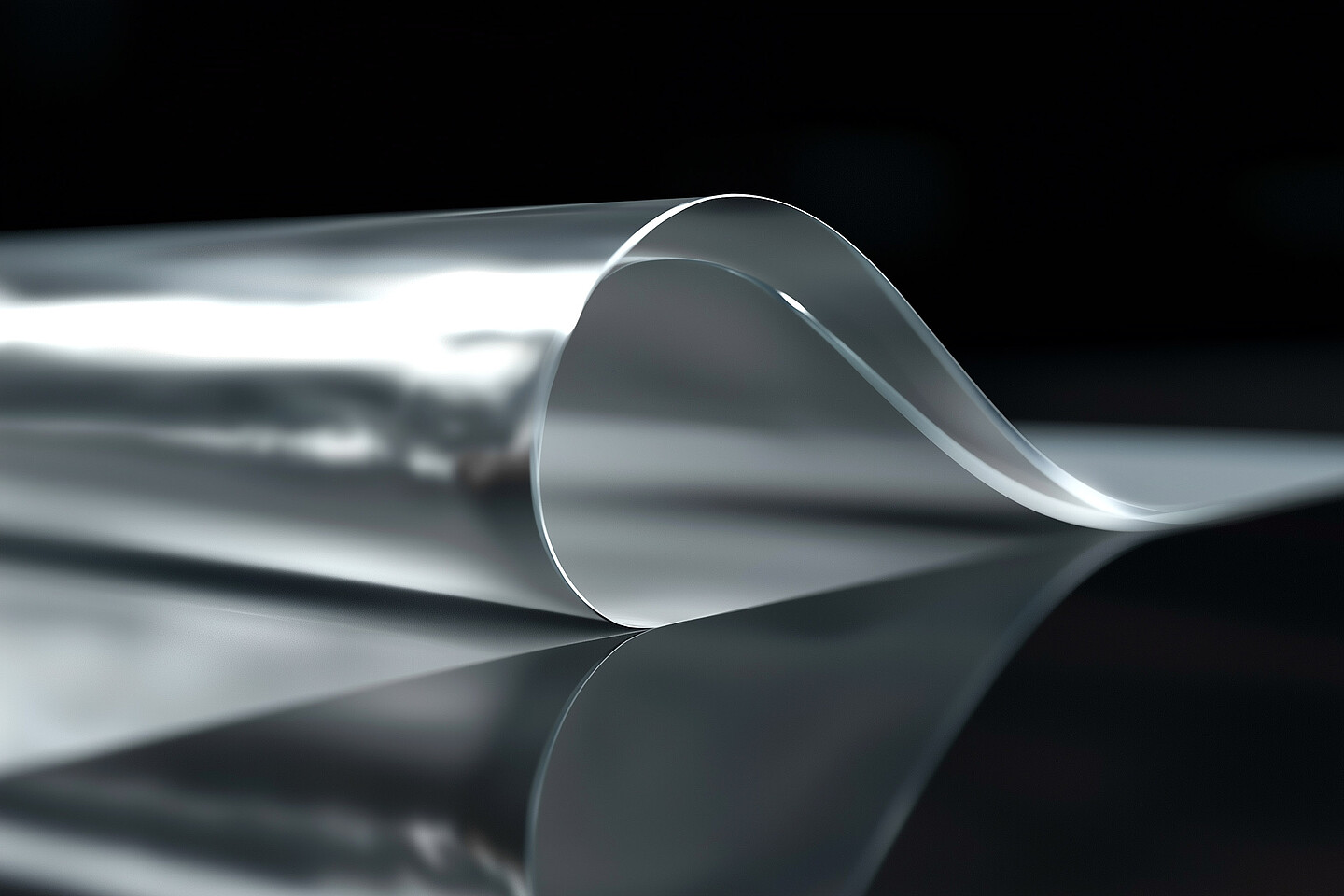

New Material Technology – High performance coated separator films

Joint venture for innovative battery technology in Europe

Horizon-Kurz New Material Technology GmbH, based in Fürth, combines the expertise of Chinese technology company JIANGSU HORIZON with that of thin-film technology specialist LEONHARD KURZ in a Chinese-German joint venture. The aim of the partnership is to establish a reliable European supplier of high-performance and extremely safe coated battery separator films. Our coated separator films have been developed to significantly improve the safety, service life and performance of lithium-ion batteries - for all applications, both in the automotive sector and for stationary storage. To this end, the company develops highly functional coating solutions for separator films for lithium-ion batteries. Efficient, reliable, sustainable - and with decades of coating expertise.

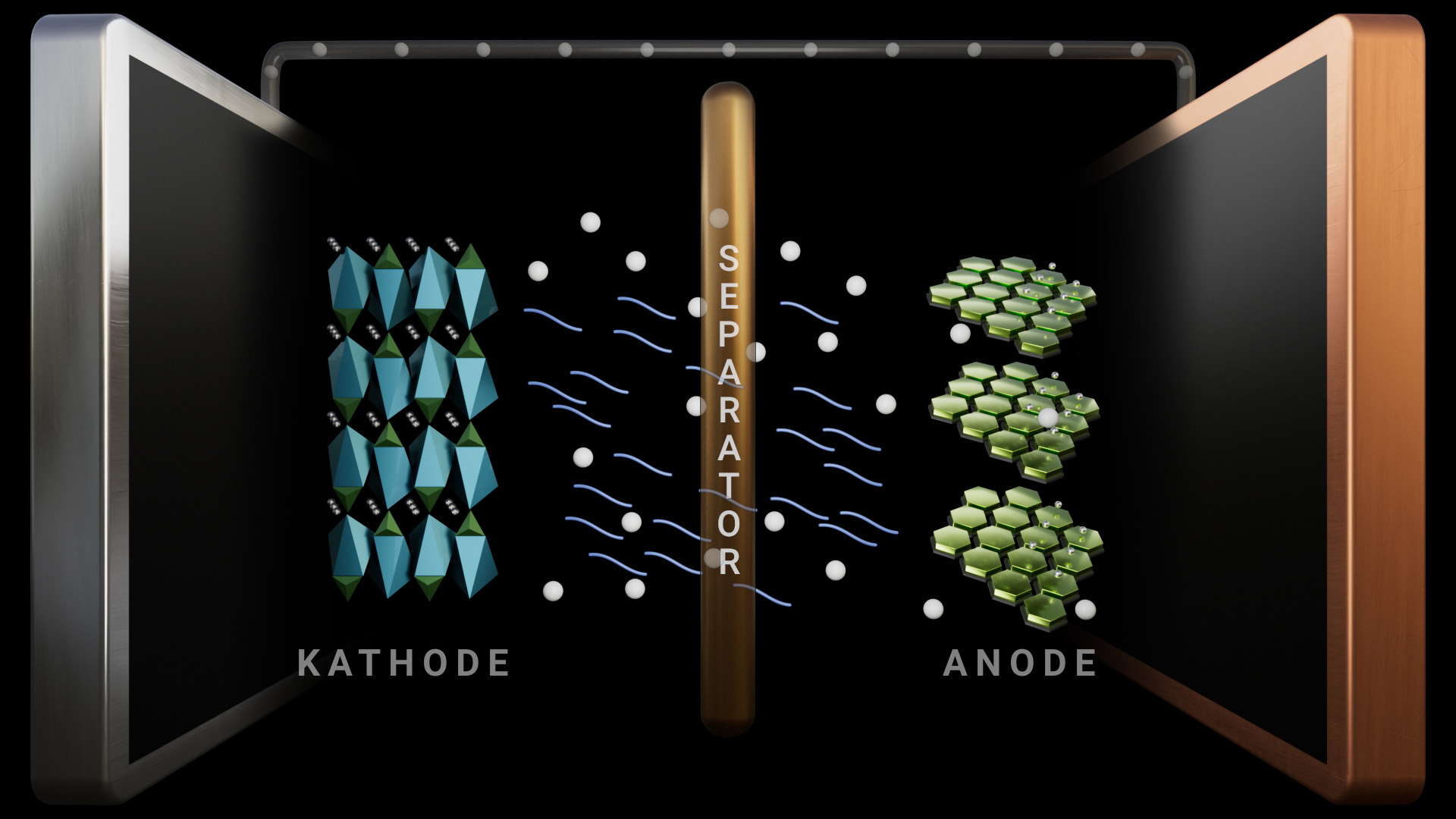

The heart of modern lithium-ion batteries

Coated separator films are key components of lithium-ion batteries. They separate the anode and cathode, but are also permeable to ions - a decisive factor for the performance and safety of batteries. Targeted coatings significantly optimize thermal stability, mechanical strength, electrolyte wetting and adhesion and thus increase the overall performance of the separator.

Sustainable and precise coating made in Europe

Technologically, ecologically and economically convincing: State-of-the-art processes ensure precise and even application of the coatings. Horizon-Kurz New Material Technology GmbH focuses on the greatest possible conservation of resources and economical use of materials. The coated separator films are suitable for various battery chemistries and all cell formats, and thus enable a wide range of applications.

Separator films

- State-of-the-art base film

- Ceramic coating on one or both sides

- With and without adhesion promoter layer (PVDF or PFAS-free)

KURZ technology in the battery

Carbon primer coatings at a glance

Current collector foils

- Carbon primer coating for current collector foils

- Special formulations for wet and dry coating processes

- Water-based and solvent-based formulations

- Customized coating thicknesses (~300 nm - a few µm)

- Protection of the current collector foils against corrosion

- Reduced internal resistance

- Improved adhesion of the active material

- Extended cycle life of the battery

Innovative solutions in development - especially for the battery environment

Fire protection for flammable materials

IGNIRIT® offers reliable protection against the spread of flames. The binder for coatings has a flame-retardant effect with ecological responsibility and can contribute to safety in e-mobility and other industries.

Heat protection for battery systems and vehicles

Our transfer coating for heat protection combines high mechanical strength with heat resistance of up to 250 °C with direct contact and up to 1,000 °C without direct contact. The protection of machine parts for the automotive or aircraft industry is possible.

Digital Battery Passport

Starting in 2027, manufacturers and distributors of a number of industrial and traction batteries will be required to provide a battery passport.

Our digital product passport system includes comprehensive information about the battery’s origin, production, composition, and end-of-life handling. It complies with the EU Battery Regulation 2023/1542 – with a ready-to-use, scalable solution from KURZ.

You profit from:

- Easy integration with your existing systems (e.g. ERP, BMS, PLM)

- Efficient operations through centralized data

- Verifiable sustainability for ESG reporting

- Market advantage, transparency, built-in product authentication

- Track and trace capability for aftermarket and returns

- Predictable costs and scaling from single units to full production

- Expandability for added value: Traceability, brand protection, or digital maintenance

Further information at https://battery-passport.kurzdigital.com/en