Decoration of natural fiber composites

Natural fiber composites are becoming increasingly important for industry. This is because they combine extreme stability with low weight and efficient manufacturing. Due to their low density and excellent mechanical and insulating properties, these materials are attractive for many applications—from car interiors to loudspeaker enclosures.

Decoration process

KURZ has developed a special decorative film that bonds with the natural fiber composite material to form a matrix when exposed to heat. And it does so quickly: a production cycle takes only about 65 seconds. The advantage for you: you save time, costs, and CO2.

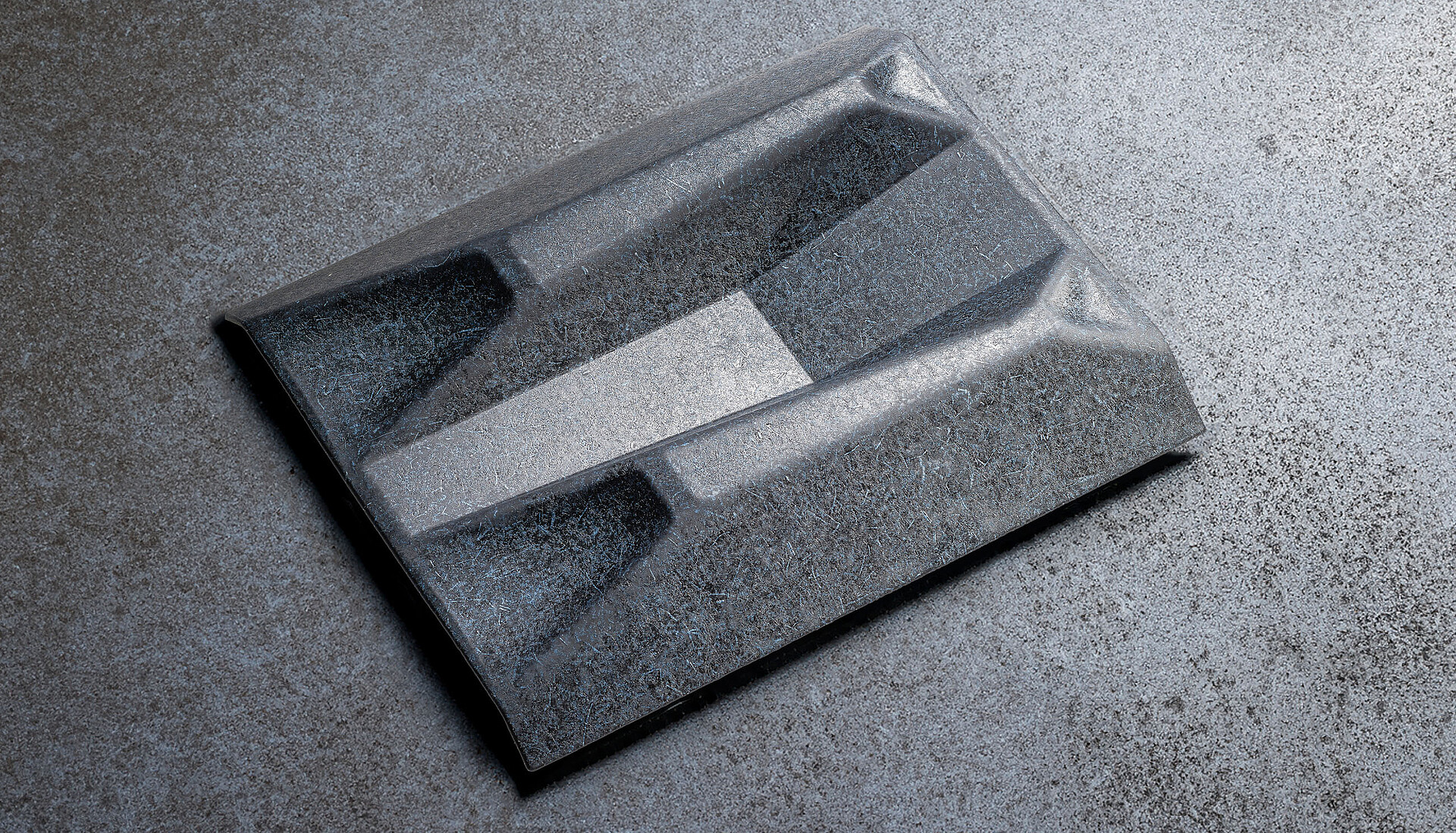

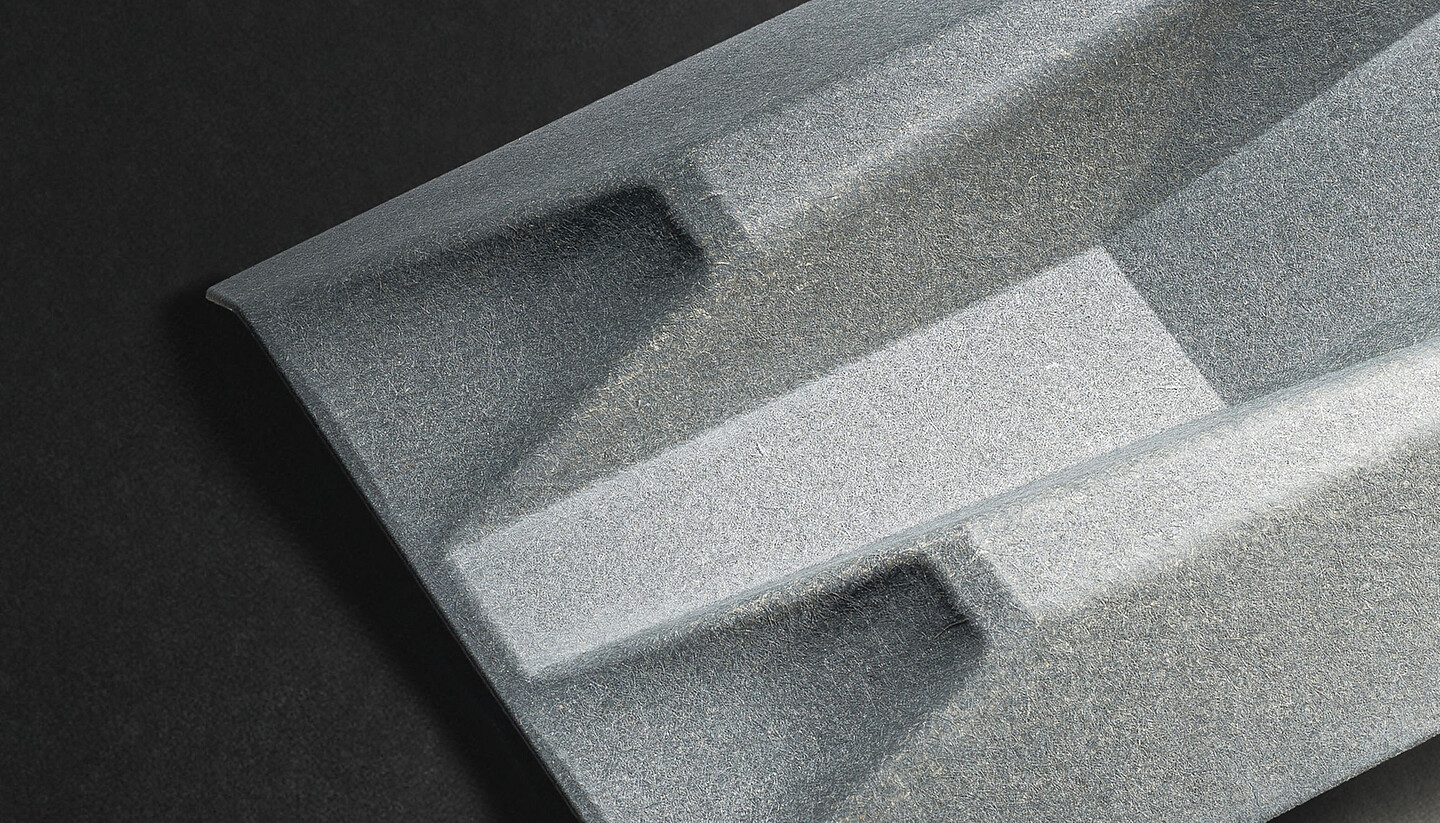

- The insert foil is placed on the composite mat made of non-woven natural fiber.

- The decorative layer is melted into the mat at the temperature and pressure required for processing the composite material and bonds to form a matrix.

- The resulting mat is then formed into the component.

Advantage of this process

- High stability of components

- Integration of reinforcements possible

- 25–40% lower component weight compared to pure plastic components

- Process suitable for series production

- Short cycle times

- Component is recyclable