Machines, dies, and tools

With the KURZ Group, machines, tool technology, stamps, and decoration are perfectly matched to your specific needs. We provide everything from a single source. KURZ subsidiary BAIER develops suitable machines especially for demanding Hot Stamping projects. The KURZ subsidiary Hinderer+Mühlich (H+M) is known for precise metal and silicone dies and a perfectly matched workpiece holder. Whether hybrid technologies that combine Hot Stamping with digital printing or specialized cleaning systems with robotic feeding - we offer the equipment that suits your requirements.

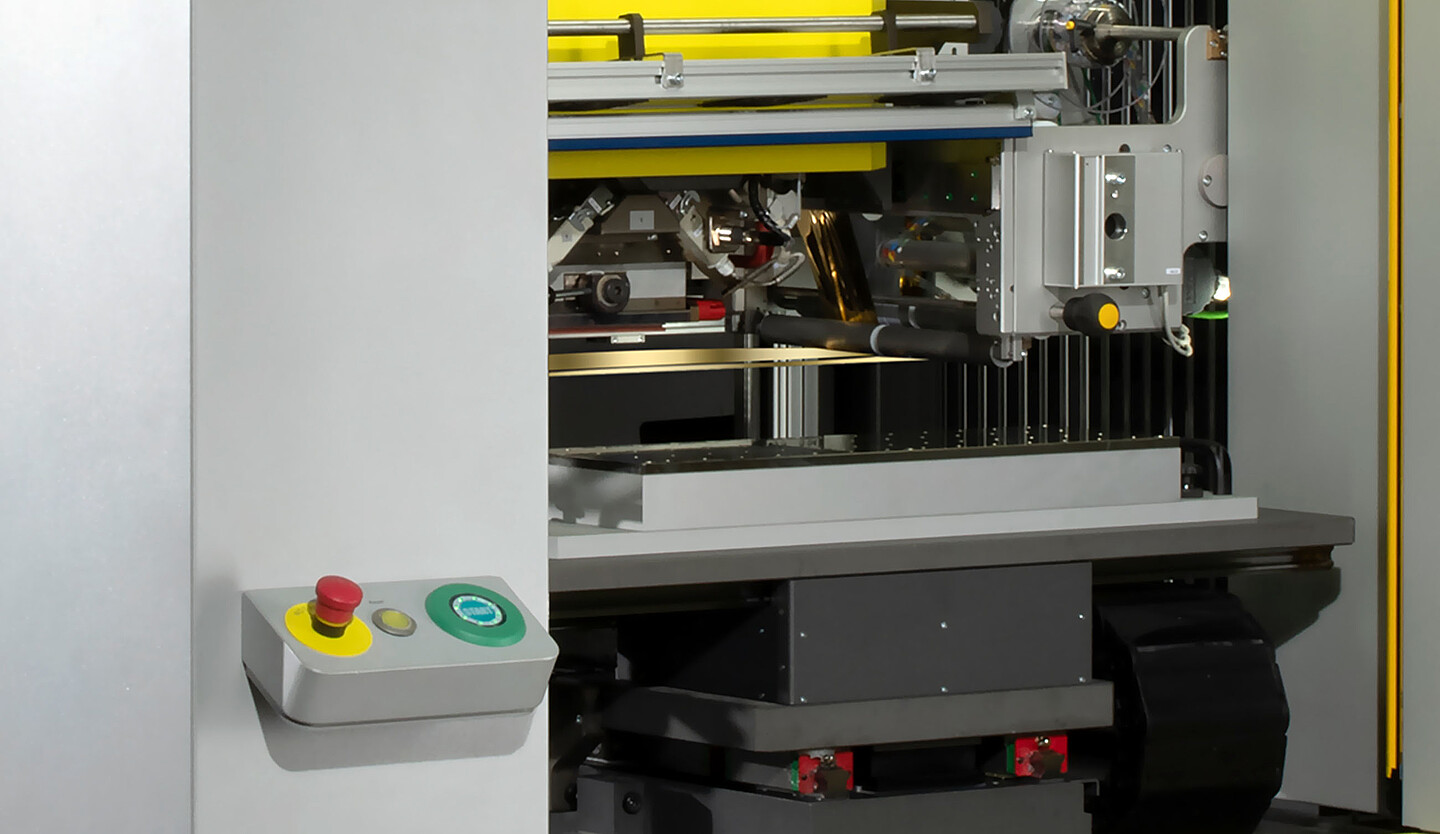

BAIER Hot Stamping machines for quality plastic decoration

Robust, reliable, always state-of-the-art - that’s what characterizes the Hot Stamping machines of the KURZ subsidiary BAIER. Our expertise ranges from simple and manually operated embossing machines to complex fully automatic embossing systems for small or large series production.

BAIER BINSPIRE

Series-ready individuality - you can resolve this apparent contradiction with BAIER BINSPIRE. This hybrid machine combines sensor integration via Functional Foil Bonding (FFB) for touch operation, and customization via digital printing in one machine unit.

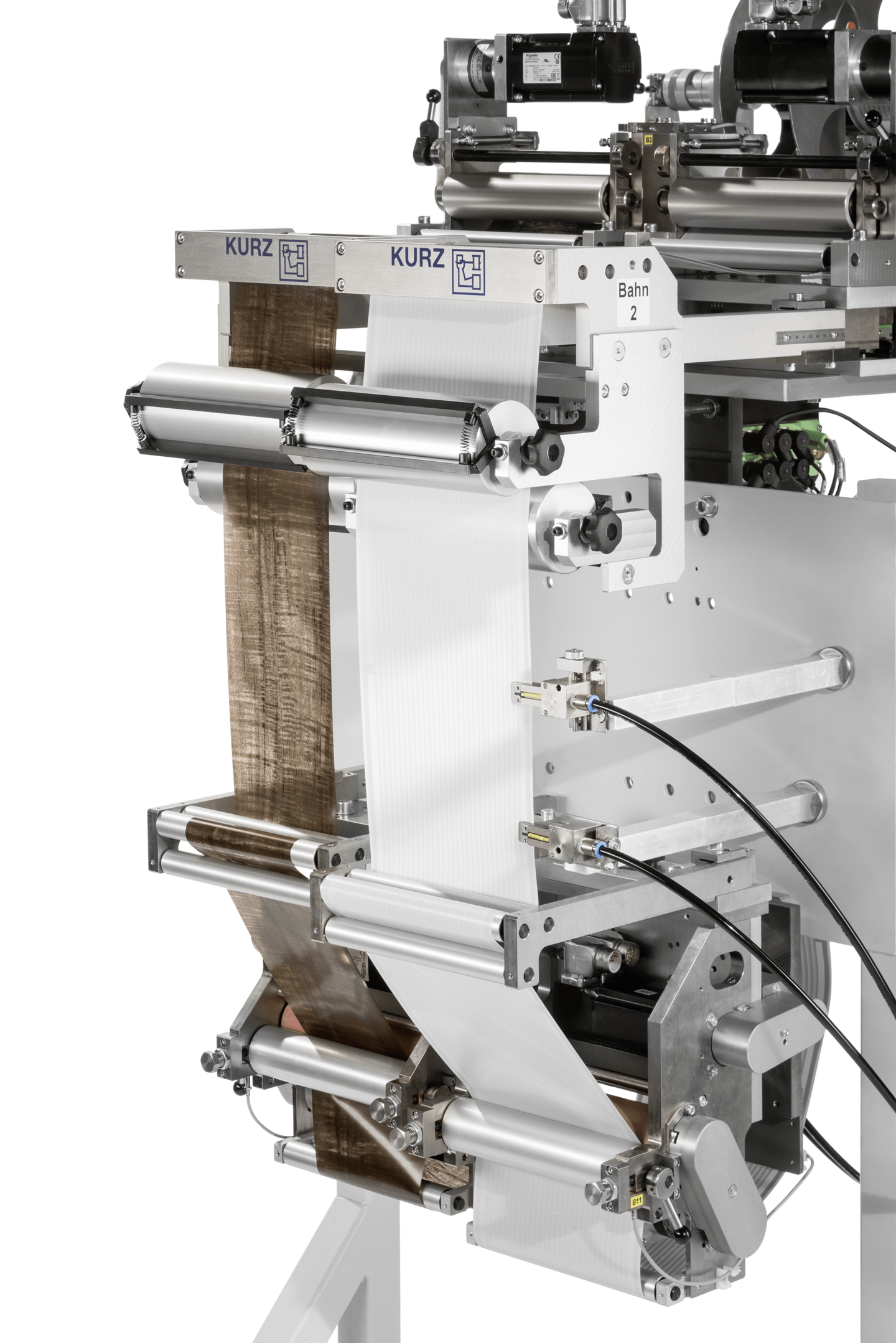

IMD foil feeders

Do you want to decorate endless films, single-image films, or even two designs at the same time? For applications in the automotive industry, for example, the C series is the right equipment for you. For double foil processing of endless decors, this series is also available with the TWIN feature. An innovative way to simultaneously decorate two different designs is the patent-pending SI-DUO series. Thus, two plastic components can be provided with different single-image or even endless decors in one operation. For example, you can design a component with a dead-front design and a black surface in our day design, and a backlit touch panel in our night design. The second surface can be transparent, with a scratch-resistant topcoat and an exceptional look. To ensure that both decors are applied accurately, extreme precision is required. At the same time, the components can be converted into functional surfaces through In-Mold Electronics (IME) by integrating a touch sensor from the KURZ subsidiary PolyIC.

Embossing stamps and tools made of silicone and metal

With Hinderer+Mühlich tools and embossing stamps, you can count on excellent embossing results. Specially made for H+M, high-performance silicones quickly reach operating temperature, so you don’t waste unnecessary time and save energy. Rely on expertise that extends from simple dies to highly complex 3D workpiece holders. Always perfectly matched to the purpose, geometry, and motif of the embossing.

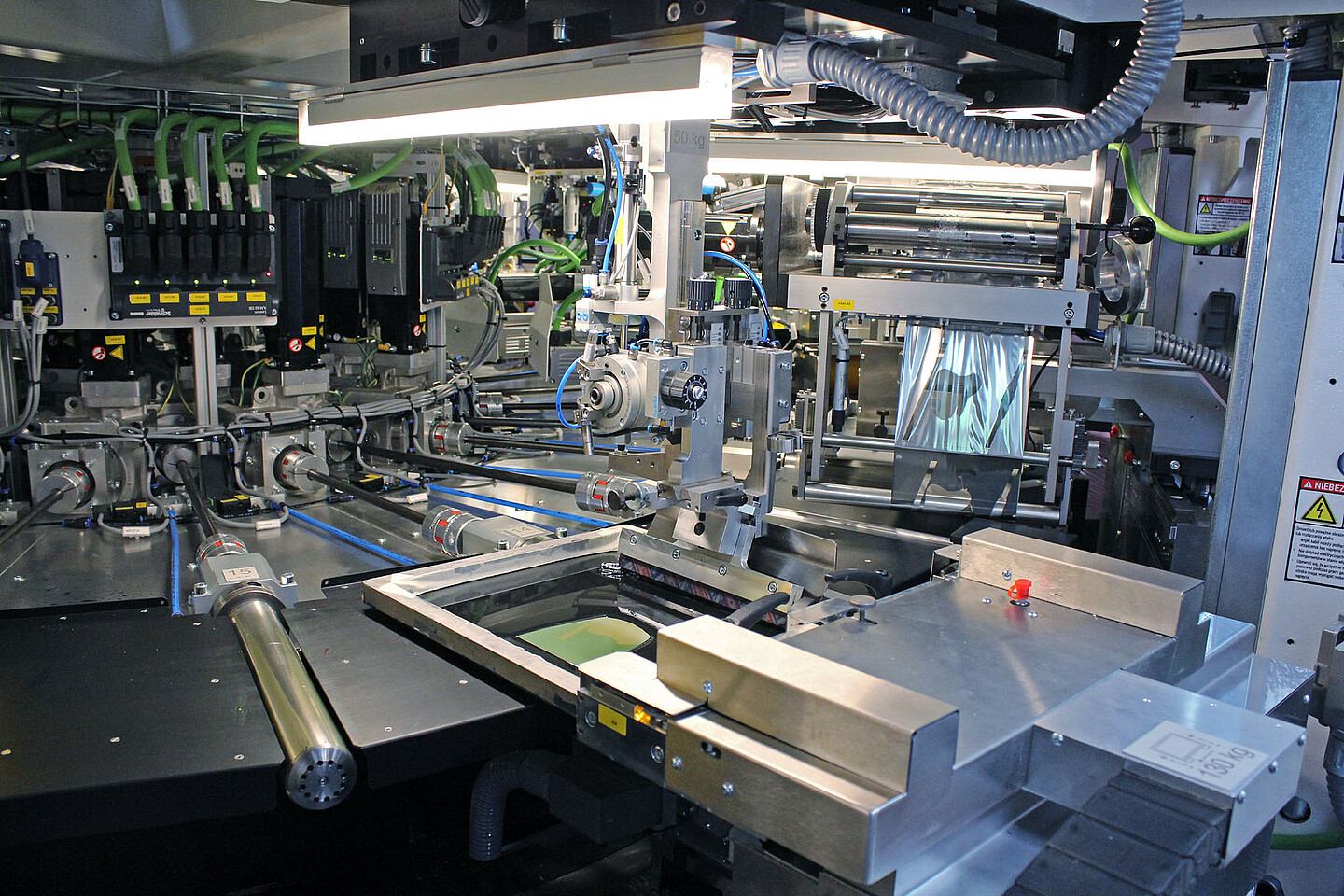

ISIMAT - Fully automatic printing presses for the cosmetics industry

For unusual hollow bodies, platen presses, or tubes with sophisticated shapes, KURZ subsidiary ISIMAT is the partner of choice. When planning, we consider your product requirements and technical specifications as well as individual requirements for decorating glass or plastic containers.

The machines can be integrated into your production process as stand-alone or in-line solutions. ISIMAT offers standard machines, customer-specific systems, and hybrid machines. In addition, you can combine different printing technologies in one machine, such as silk-screen printing, varnishing, and Hot Stamping.