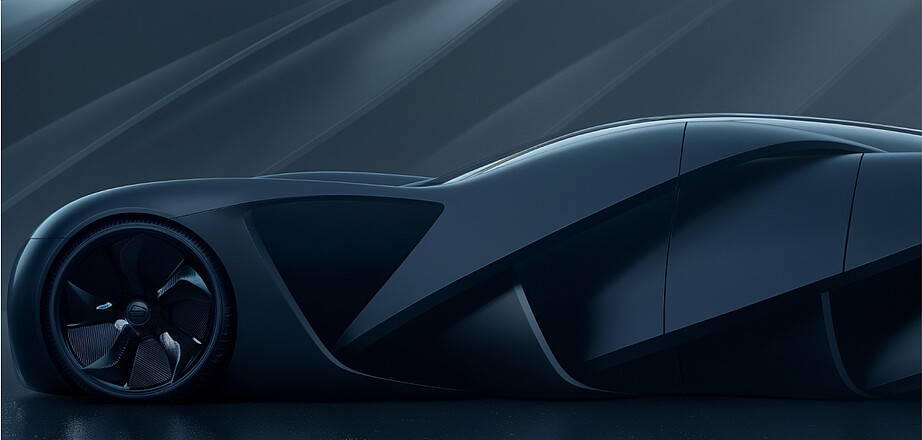

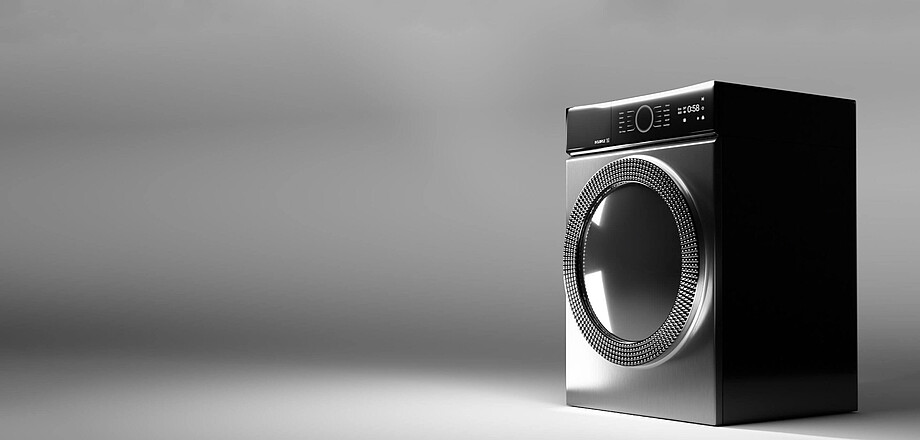

As a broad-based thin-film specialist,

we develop and produce unique and sustainable surface decorations for cars, notebooks, household appliances and many other products. In doing so, we always focus on sustainability and the careful use of our natural resources.

How do new trends influence surface design? How can functionality and durability be translated into smart, attractive finishes? How can decorations become even more sustainable? Discover exciting projects, some of which have won design awards.

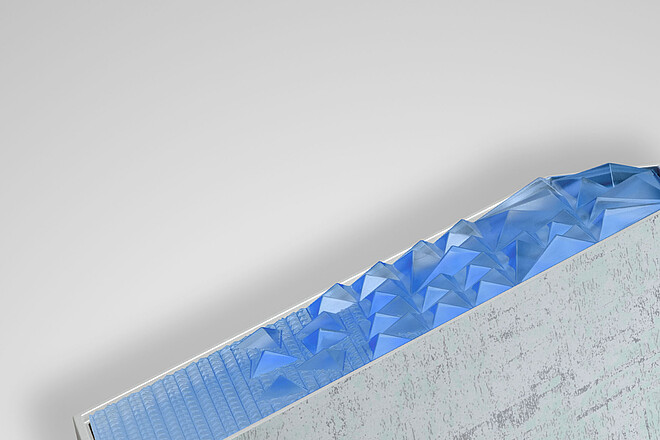

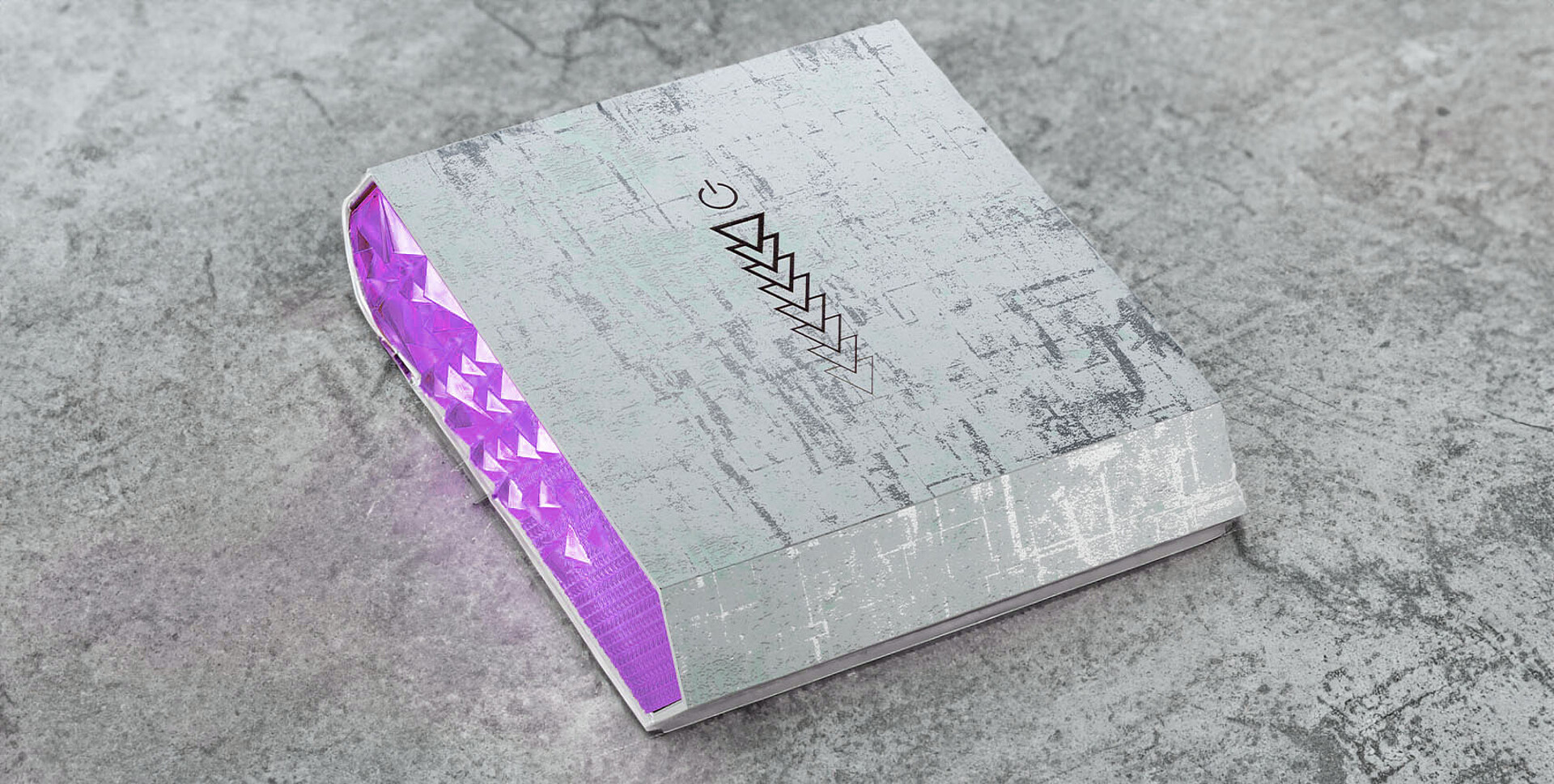

Sustainably reducing CO2 emissions

To reduce our environmental footprint, we have developed a modular system - Conscious Concept. This brings you a significant step closer to climate neutrality.