Smart Home &

Home Appliances

Tomorrow’s generations of appliances are conquering the living space, the trend toward closed surfaces is fundamentally changing designs and components. KURZ lets you experience what is possible thanks to extremely thin film technology, premium finishing, new materials and integrated sensor technology: New generations of products become more individual, but at the same time more robust, durable, long-lasting and sustainable. And as a manufacturer, you can profit from a continually optimized value chain.

Shy tech design front panel

This panel stands out due to its elegant dark design. The intuitive HMI user interface only appears in the form of a high-resolution LCD or LED display when the display is touched. The advantage of this shy tech design is that the controls can be freely assigned. Decoration takes place in a single step via the economical IMD process, in which the panel is injection-molded and decorated at the same time.

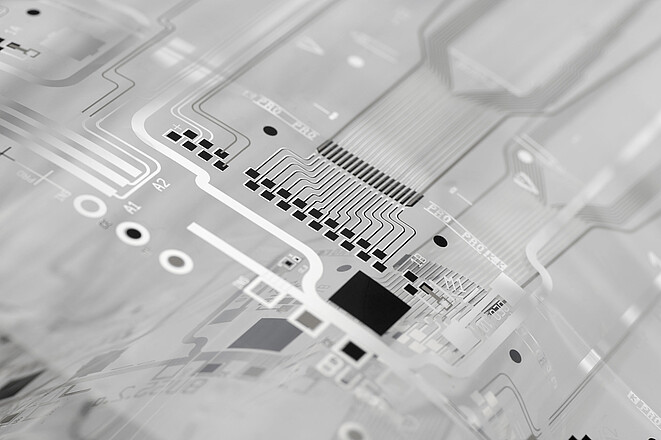

Sensor technology for LED and LCD displays

The basis of the human-machine interface is the sensor technology of KURZ subsidiary PolyIC, which offers touchscreen and touchkey sensor solutions for a wide range of requirements.

The cost-effective and simple multi-touch sensor solution for the LCD area enables flexible programming of a wide range of operating modes (multi-finger operation) and thus provides ideal conditions for homogeneous, seamless display integration.

The translucent touch sensor for LED displays has an integrated diffuser and a laser-enabled decorative layer. This eliminates the need for additional components (light-diffusing plastic inserts) for homogeneous illumination of symbols and characters. Symbols and national languages can also be customized at the end of the process chain via laser edging. Customers benefit from a lower number of integration steps and a very delicate display of symbols and controls.

Intelligent interface heroes with IMD UNIFY

Home appliances become stylish eye-catchers with IMD UNIFY. The basic decoration is produced in series in the economical IMD process and can be subsequently customized via digital printing. In combination with freely assignable buttons, special edition designs, different language versions, logo variants, and much more are created. An additional bonus for the environment: You save on buttons and switches, numerous transport routes and work steps. Your CO2 balance will improve.

The advantages of customization with IMD UNIFY:

- Series production and individualization can be achieved at the same time

- Touch operation with seamless, homogeneous surfaces, with backlighting and curved control panels or displays

- Unlimited design and customization options

- Integration of appliances into open plan living areas

- Efficient processes, as material and process steps are reduced

- Can be used for recycled materials

- Surfaces are recyclable

- Incredible design variety

- Trends can be implemented quickly

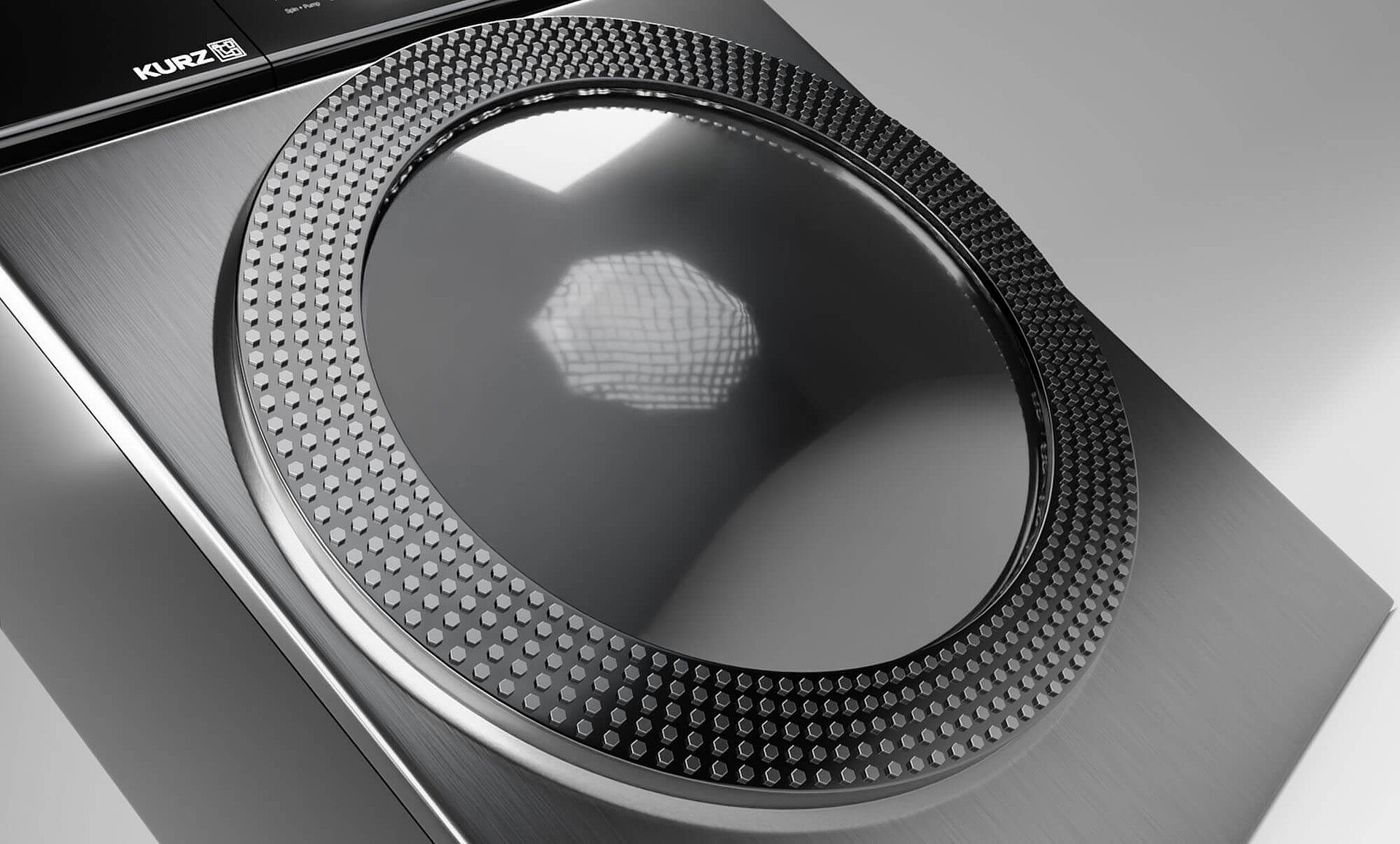

Real metallization

Matte, glossy, brushed, backlit – KURZ chrome decorations have many faces. Full-surface or partial metallization using hot stamping gives you THE sustainable alternative to electroplating. The finishing, which can also be applied partially, uses wafer-thin real metal and is also extremely economical, recyclable, and suitable for recycled materials.

Benefits of real metallization

- Series-ready, proven process technology

- Low-carbon process

- Environmentally friendly compared to electroplating

- Exact finishing including the bull’s eye edge

- Can also be applied partially

- Recyclable

- Suitable for recycled materials

All finishing techniques from a single source

The entire range of manufacturing processes developed by KURZ can be seamlessly integrated into your existing production lines. Regardless of the location of your production or final assembly, our know-how is at your disposal: for increased efficiency, lower costs, more sustainability, and leaner value chains.