Haptic effects

Haptic effects of plastic decorations are far more than a design effect, they are a part of your brand. Feeling completely natural, the soft-touch surfaces are sure to surprise. Grippy, velvety, smooth, brushed, metallic, warm – suitable for the product and for anything from large series to small series production or custom-made products. Make the choice easier for your customers and turn your products into a sensory highlight. Also suitable for special sizes and small series.

How haptic effects will shape the future of plastic surfaces:

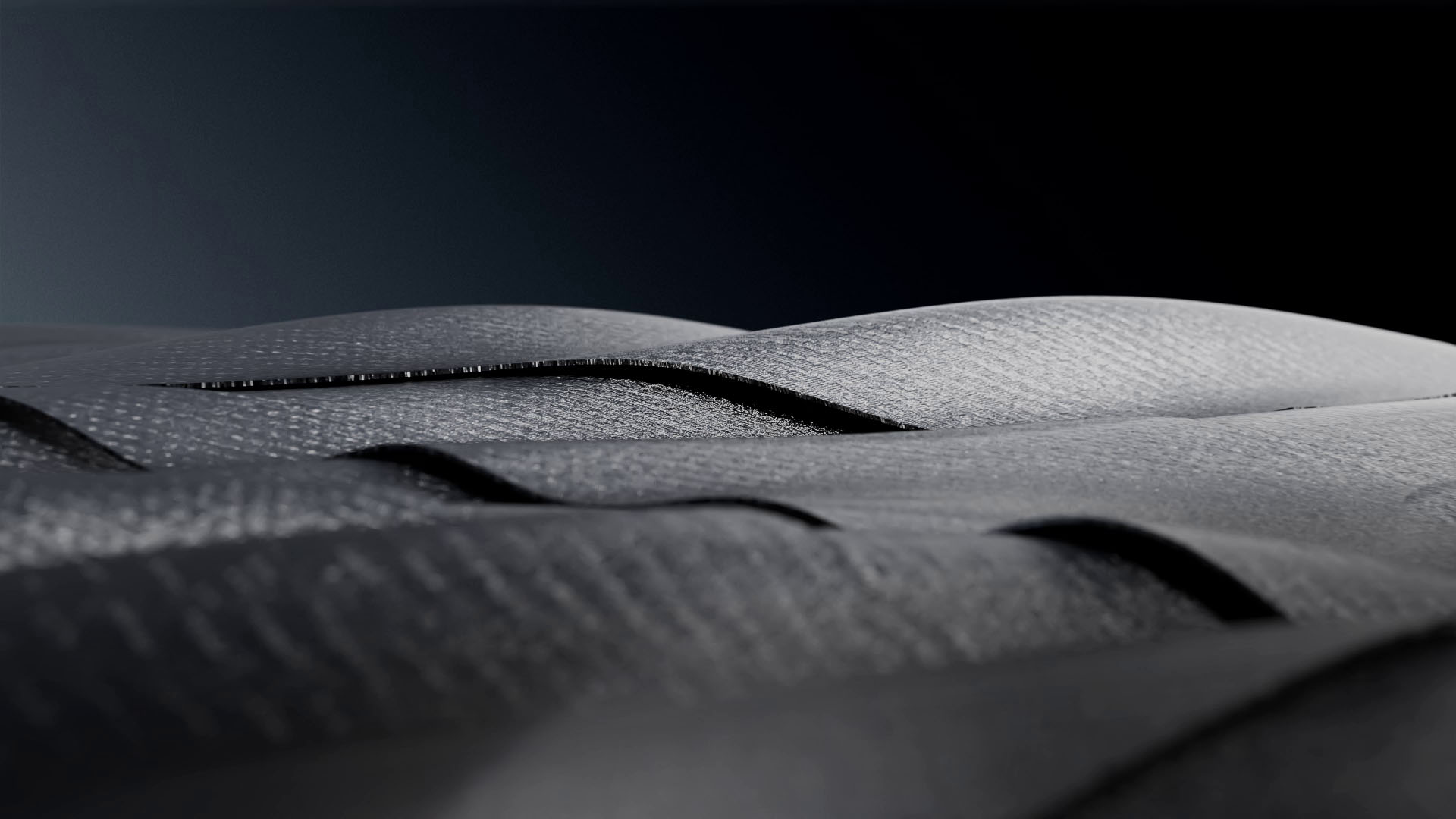

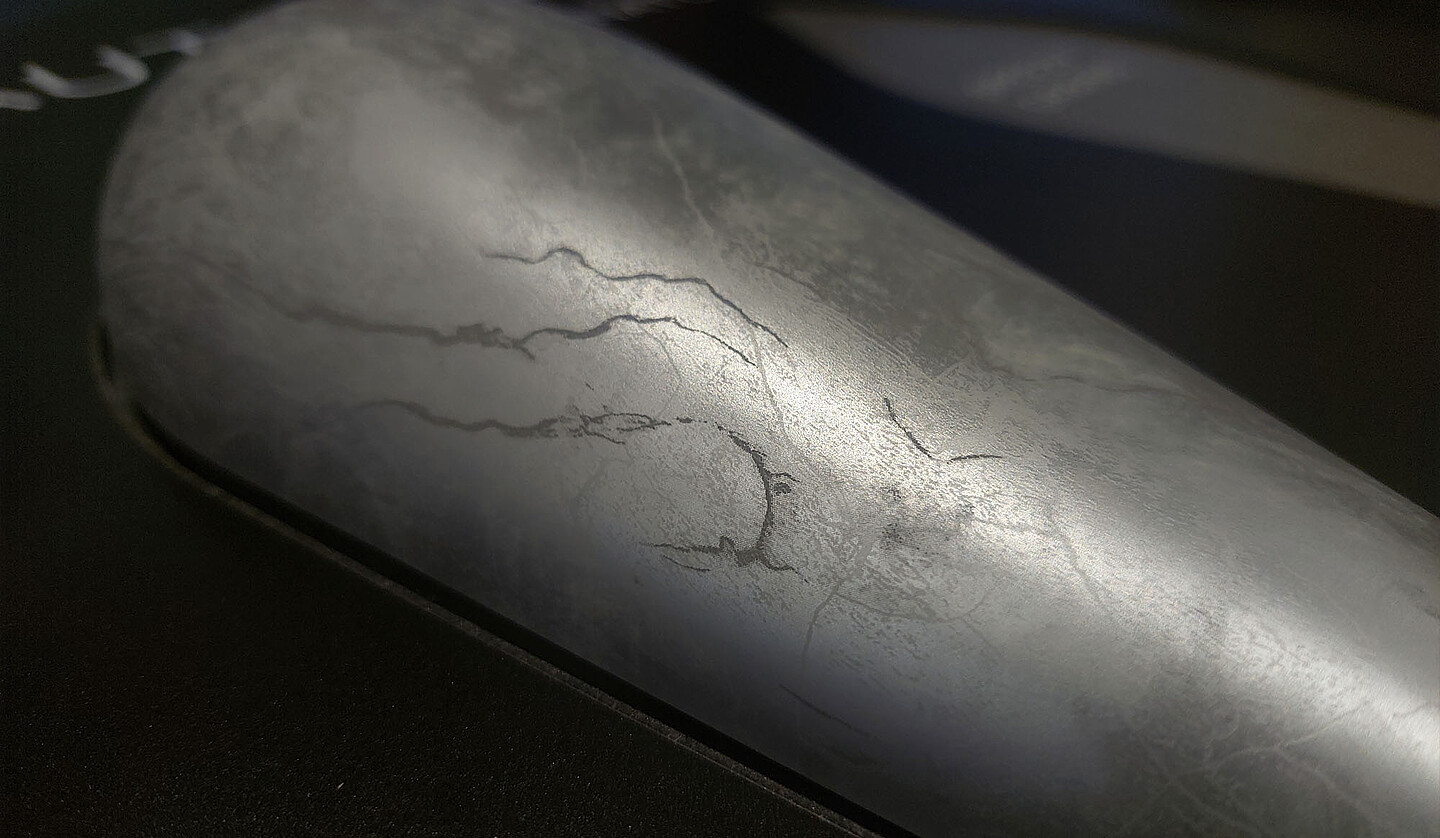

Fabric, leather, and other haptic designs feel deceptively genuine

Natural surface designs offer more variety than original materials when it comes to form, design, and functionality

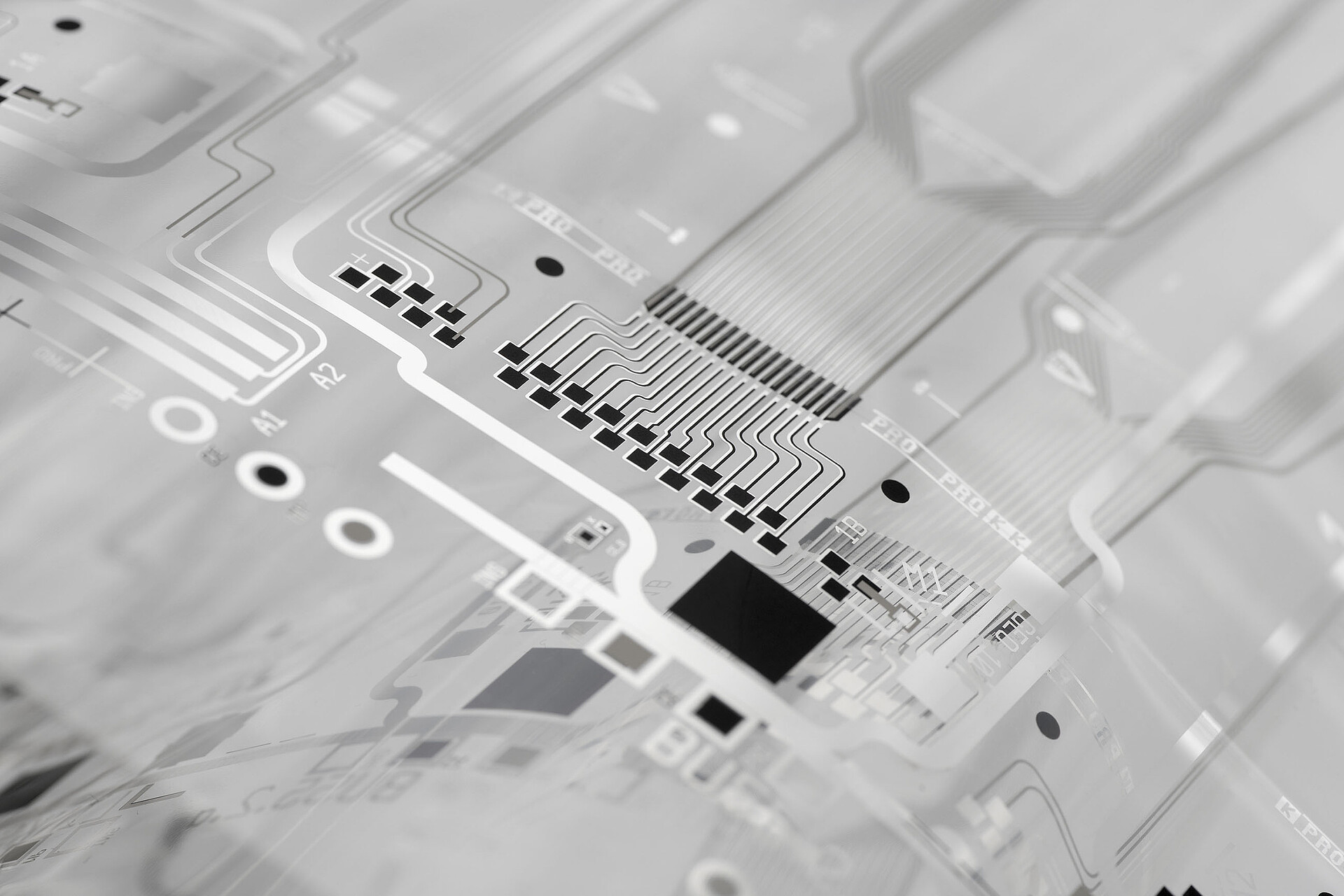

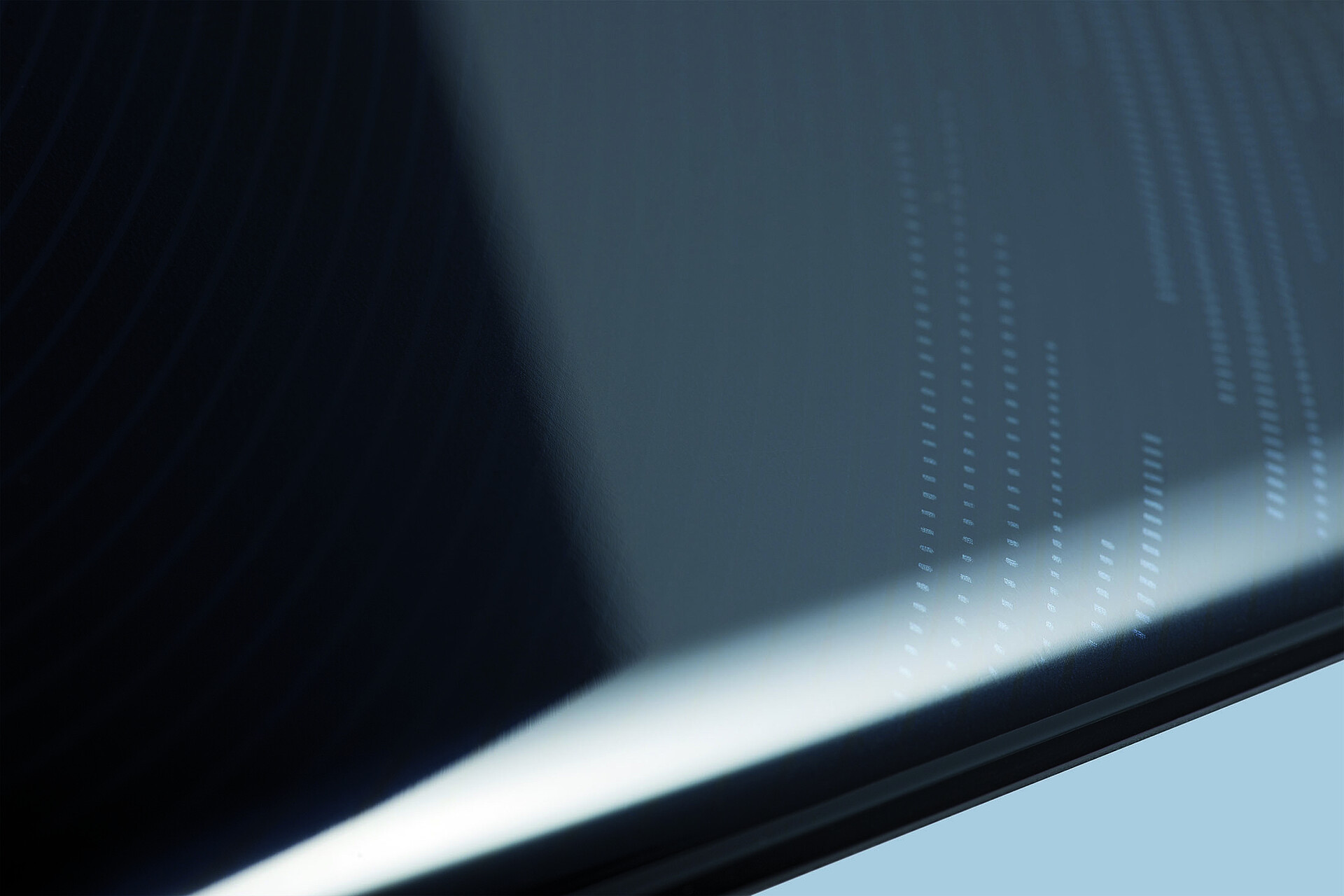

Touch control interfaces in shy tech design are emphasized haptically and intuitively

Design for Recycling: The recyclability of the decorated components remains intact

IMD technology makes the production process highly efficient

Hoher Oberflächenschutz gegen Kratzer, Abrieb, UV-Strahlung

New: Haptic effects can now also be transferred to 3D plastic surfaces with IMD decoration via digital printing. Both sides of the PET carrier are used in this process. While ultra-thin coating layers are applied to the front side, the second process step on the rear adds the desired structures via digital printing. In addition to tactile designs, cleverly applied light effects create an innovative impression. Also suitable for special sizes and small series.

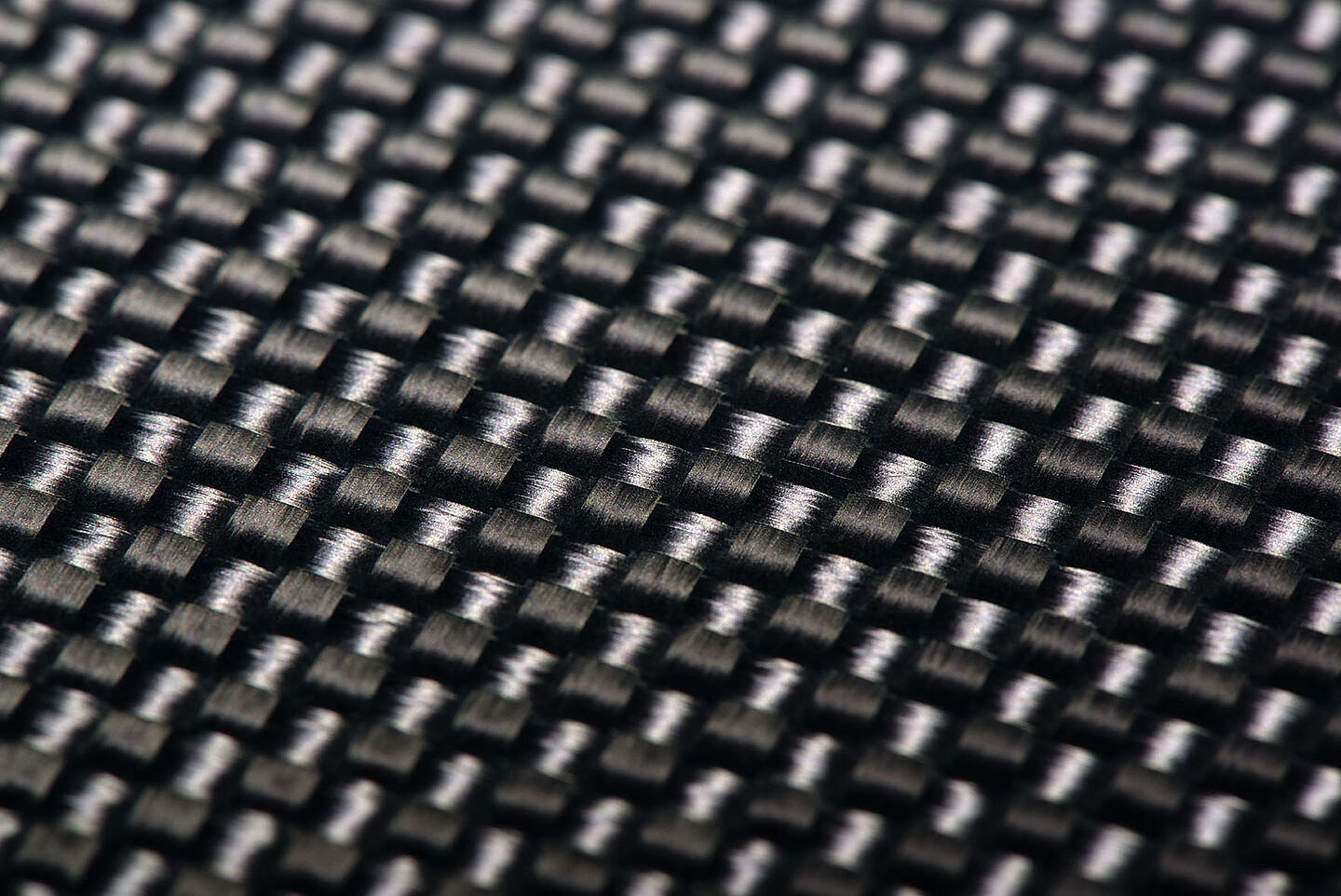

Spectacular surface effects for fiber-reinforced plastics

Decorating composite materials in lightweight construction is a special challenge. You can gain a competitive edge in the consumer electronics segment. Together with our partners, we realize trendy design effects with matte or slightly textured surfaces, such as transparent soft touch, which emphasizes the carbon look, or wood effects. We are working at full speed on the production maturity of our IMD coating in various designs. Your benefits: Save up to 60% on costs and 70% on CO2 with this decoration process.