KURZ is your partner

for ultra-thin surface decorations that are thinner than human hair. The company’s lean processes use very little material, reduce CO2 emissions considerably and are suitable for use on both recycled and virgin materials. The result: Breathtaking, recyclable plastic surfaces.

Part Advisor

With the KURZ Part Advisor, you can find out in just a few steps which decoration solution best suits your component. You will receive feedback from our specialists within 24 hours..

Decoration processes

Hot stampingFlexible, with maximum precisionDecoration and sustainable metallization of surfaces, full-surface or partial

Hot stampingFlexible, with maximum precisionDecoration and sustainable metallization of surfaces, full-surface or partial In-Mold Decoration (IMD)Reduces the carbon footprintFor surfaces with haptic and tactile effects. In one single process step, fully decorated parts are created, even with complex geometries.

In-Mold Decoration (IMD)Reduces the carbon footprintFor surfaces with haptic and tactile effects. In one single process step, fully decorated parts are created, even with complex geometries. IMD VARIOFORM®3D surface decorationEfficient decoration of complex 3D components - perfect for small series and custom designs.

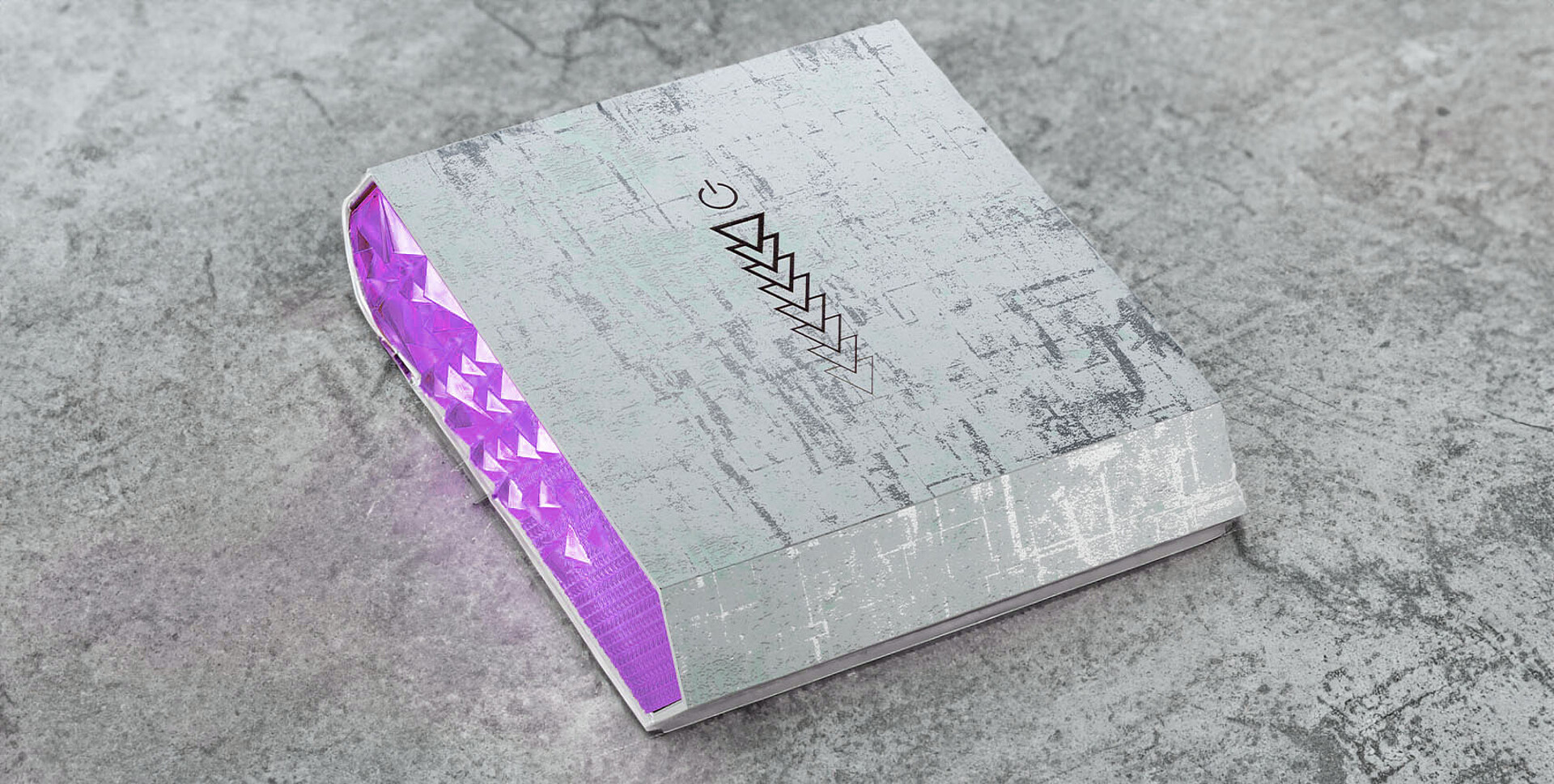

IMD VARIOFORM®3D surface decorationEfficient decoration of complex 3D components - perfect for small series and custom designs. IMD UNIFYIndividualization by digital printingCustomization with series advantage down to a quantity of 1. Suitable for special editions or for special requirements.

IMD UNIFYIndividualization by digital printingCustomization with series advantage down to a quantity of 1. Suitable for special editions or for special requirements. Insert MoldingFor complex geometriesHot stamping, deep drawing, and injection molding for the decoration of heavily shaped components.

Insert MoldingFor complex geometriesHot stamping, deep drawing, and injection molding for the decoration of heavily shaped components. Print-Mold Design (PMD)Special screen printing technologySpecial silk-screen printing technology for spectacular interior designs with depth effect and feel

Print-Mold Design (PMD)Special screen printing technologySpecial silk-screen printing technology for spectacular interior designs with depth effect and feel Digital InLINE FOILING and Indirect Digital DecorationTwo decoration processes in one machine cycleIn the first step, cosmetic tubes are metallised. In the second step, they are individually decorated using digital printing. The result: seamlessly decorated tubes.

Digital InLINE FOILING and Indirect Digital DecorationTwo decoration processes in one machine cycleIn the first step, cosmetic tubes are metallised. In the second step, they are individually decorated using digital printing. The result: seamlessly decorated tubes.

Sensor integration

Functional Foil Bonding (FFB)Subsequent sensor integrationPrecise sensor integration even for complex shapes directly after the injection molding process.

Functional Foil Bonding (FFB)Subsequent sensor integrationPrecise sensor integration even for complex shapes directly after the injection molding process. In-Mold Electronics (IME)Simultaneous sensor integrationDecoration and sensor integration take place in one process step. For a shorter value chain and reduced energy consumption.

In-Mold Electronics (IME)Simultaneous sensor integrationDecoration and sensor integration take place in one process step. For a shorter value chain and reduced energy consumption.

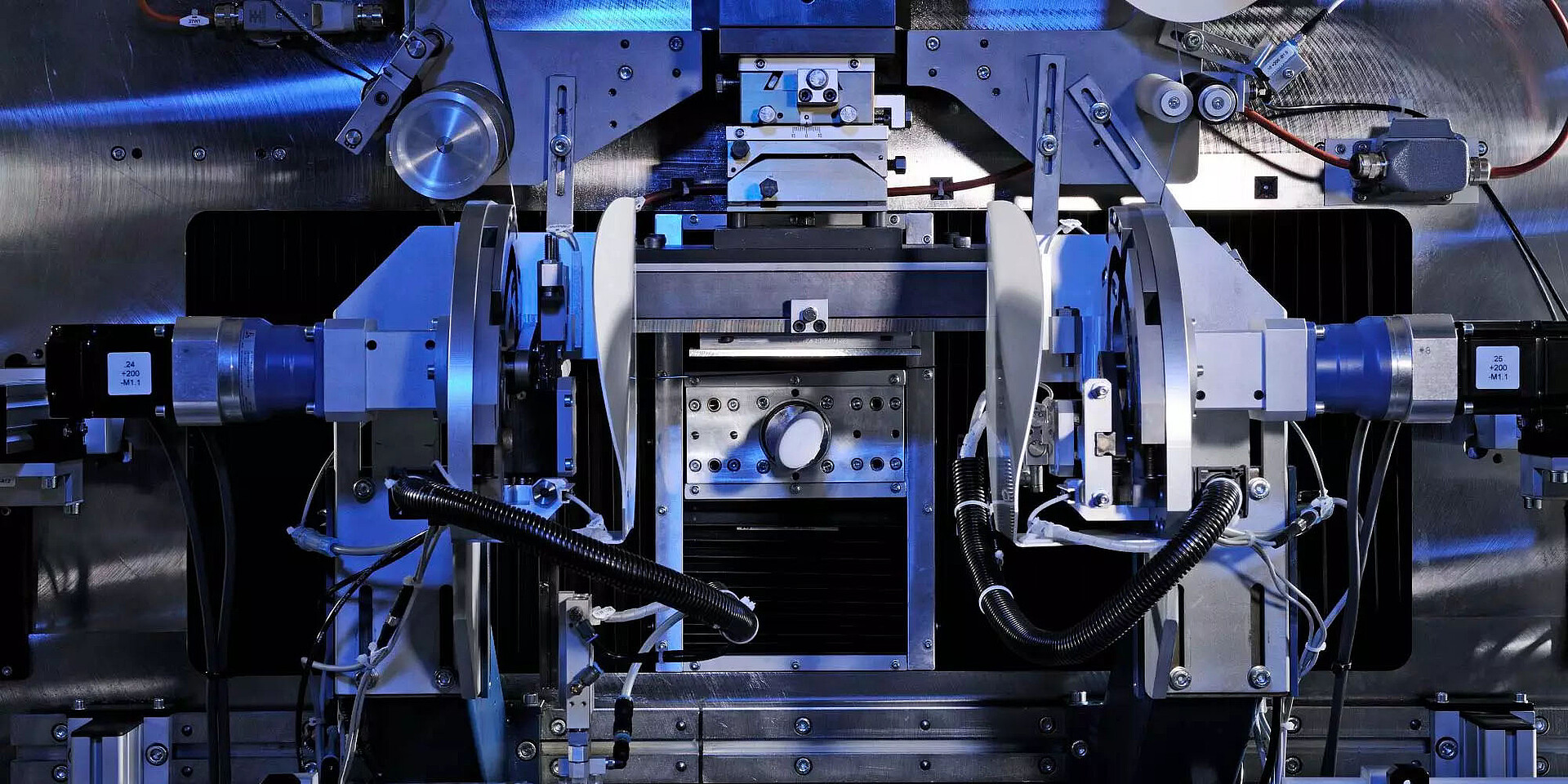

Machines, dies, and tools

From specialized embossing machines to innovative printing systems for tubes and containers, KURZ - together with its subsidiaries BAIER, Hinderer+Mühlich (H+M), and ISIMAT - offers everything from a single source for efficient and consistently high-quality product design.