Surfaces are finished

to appeal to the senses. We offer innovative designs, excellent decoration processes, and smart sensor technologies. From nature-inspired to interactive finishes, from wood looks to metallic and haptic effects - even day-night designs and backlighting open up new dimensions for individual solutions.

Making every product unique

Our solutions impress in terms of design and technology. Inspiration from nature can be combined with touch functions or shy tech designs. Matte or shiny wood-look surfaces can be combined with metallization and haptics. Adding day-and-night designs or backlighting creates a new world for plastic surfaces. If you wish, we’ll support you from the first idea to the finished product. In doing so, we make sure that the selected products and methods fit precisely into your value chain. Consistently high quality and production reliability are a matter of course for us. Team up with KURZ to experience leaps in plastic decoration development.

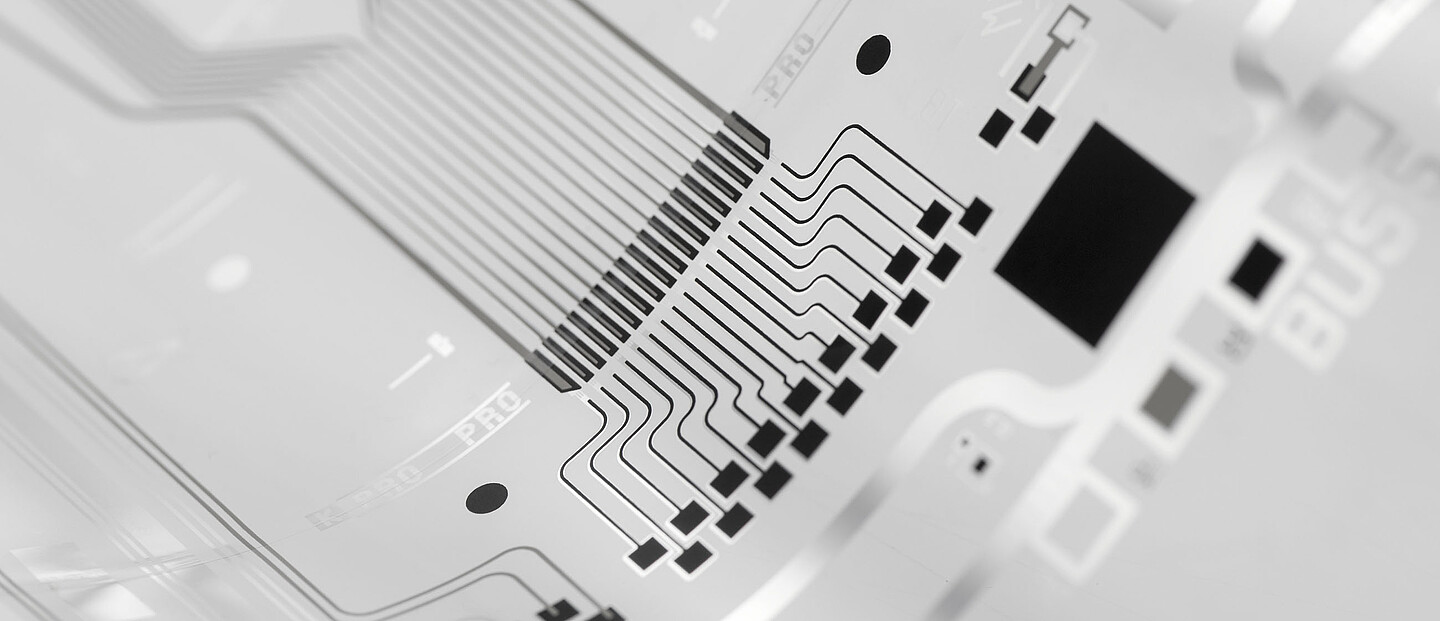

Touch sensors

Whether home appliances, consumer electronics, or automotive, touch control and sensor technology have fundamentally changed the design and functionality of devices. Together with our subsidiary PolyIC, we develop state-of-the-art sensor technologies such as the PolyTC® sensor film. Take your products to a new level. Discover how easy it is to integrate custom sensors and touch control seamlessly.