Bavaria Innovation Award 2020

IMD VARIOFORM® with Functional IME

As the next generation of leading finishing technologies, our IMD VARIOFORM® process with In-Mold Electronics (IME) was awarded the third main award at the Bavarian Innovation Prize 2020.

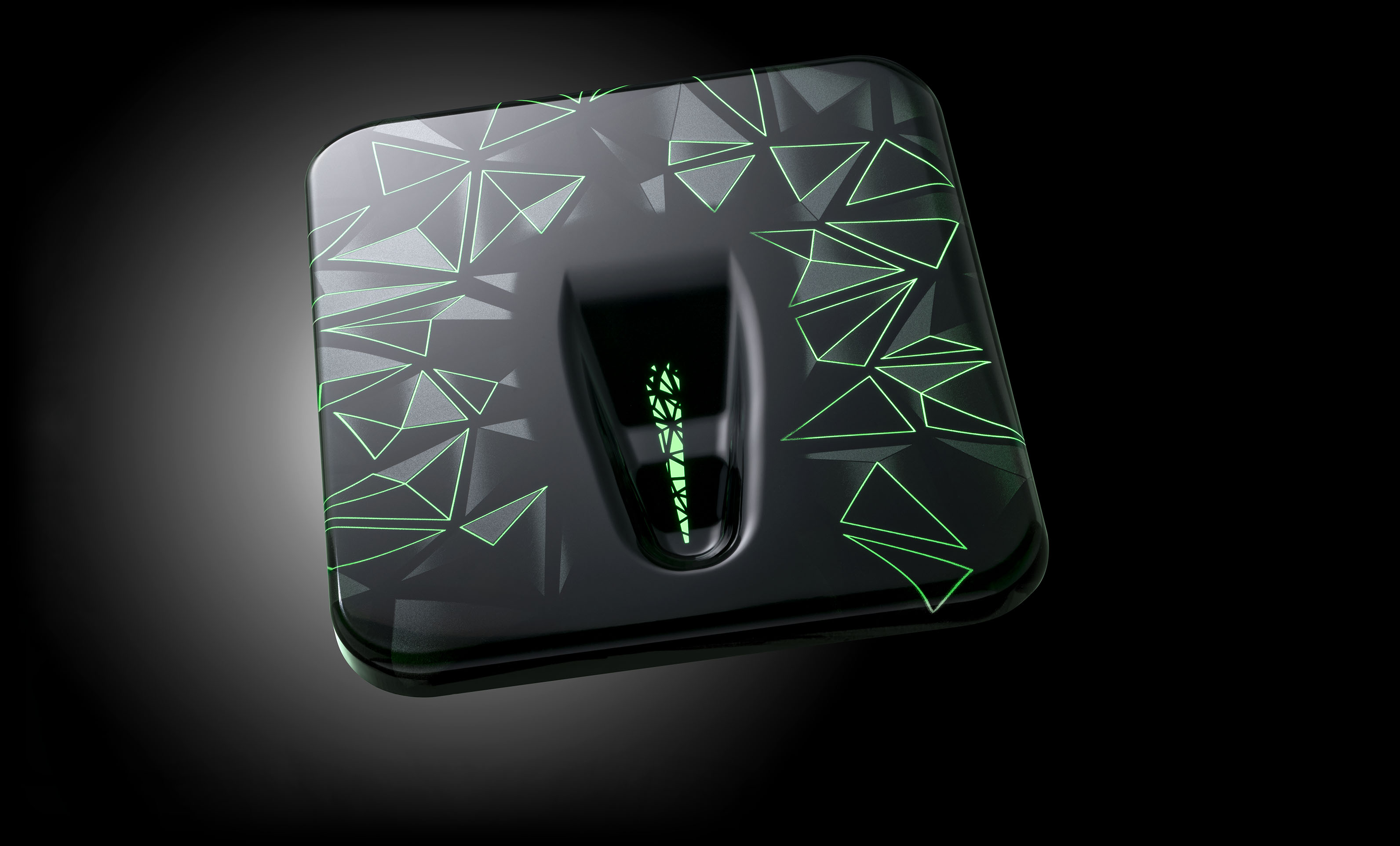

By bundling the four processes of decorating, thermoforming, back-injection molding, and punching, we achieve unprecedented performance levels when it comes to decorating smart three-dimensional plastic components with matching touch sensors. An example of this technological innovation is a specially designed component with slider function and backlighting.

But our innovation is not only ground-breaking for applications with a human/machine interface in the automotive industry: Household appliances and consumer electronics can also become functional designer objects in this way. These synergies let you achieve maximum efficiency and the best possible cost optimization, coupled with unmatched creative freedom when it comes to design.

Making every product unique - true to our mission, we are constantly on the lookout for new, sustainable, and efficient solutions. By combining IMD VARIOFORM® with IME, we have succeeded in achieving a highly efficient development, which has been awarded the Bavarian Innovation Prize 2020. Three-dimensional HMI components can be manufactured in a single work step, with maximum design freedom. The four processes of thermoforming, decorating, sensor integration, and punching take place in the injection molding tool in one single processing phase. The result: Sophisticated geometries and individual design solutions that don’t restrict the recyclability of the components.

The requirement

HMI (Human Machine Interface) components have increasingly demanding geometries. This is why they need sensors that function flawlessly even on strongly curved or bent surfaces. Our aim here is to develop sustainable solutions that allow unmatched design freedom. With the combination of IMD VARIOFORM® and IME, we have succeeded in achieving this impressively.

The solution

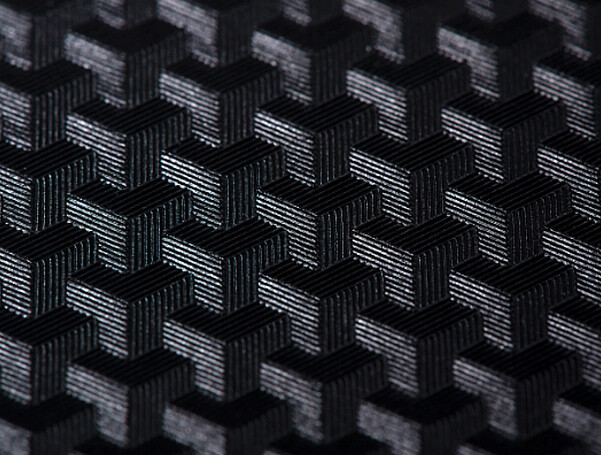

Whether individual or series production, this process offers maximum cost-effectiveness. With the award-winning solution from KURZ, you can simultaneously shape, decorate, integrate a sensor, and punch the 3D component. Thanks to their ultra-thin metal-mesh support structure, the deployed PolyTC® sensors accommodate the 3D deformation and adapt flexibly to even challenging shapes. Another plus: You can use single-image or continuous designs as well as full-surface or partial backlighting. In addition, recycled material can be enhanced and customized at the same quality as new material. The solution is an excellent triad of economy, flexible design, and sustainability.

Here´s how we won over the jury:

- Suitable for single-image and continuous designs

- Bundling of the four processes of thermoforming, decorating, sensor integration, and punching - in one single processing phase

- Maximum cost-effectiveness, for both large and small series

- Also suitable for extremely deformed geometries

- Both recyclables and new materials can be used