In-Mold Decoration (IMD)

In-Mold Decoration: the first impression counts

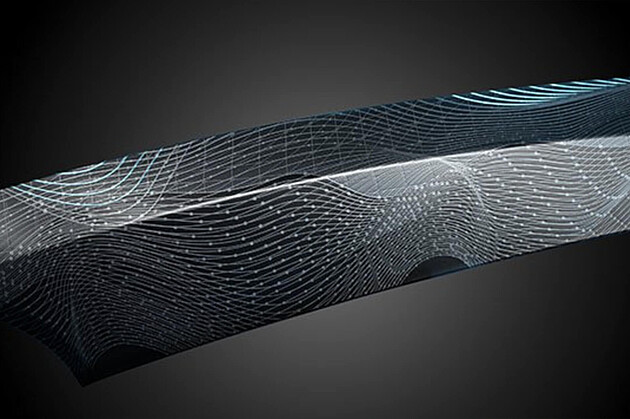

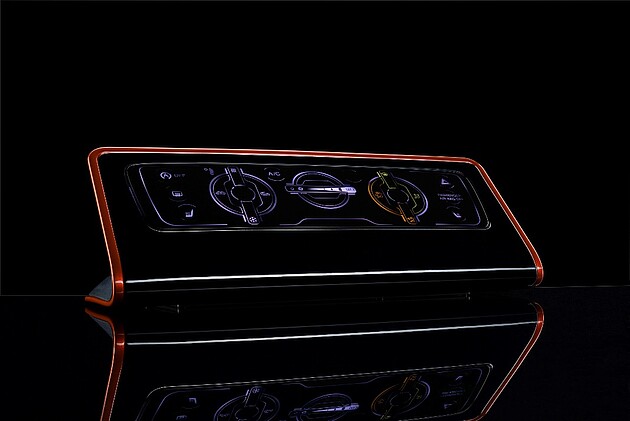

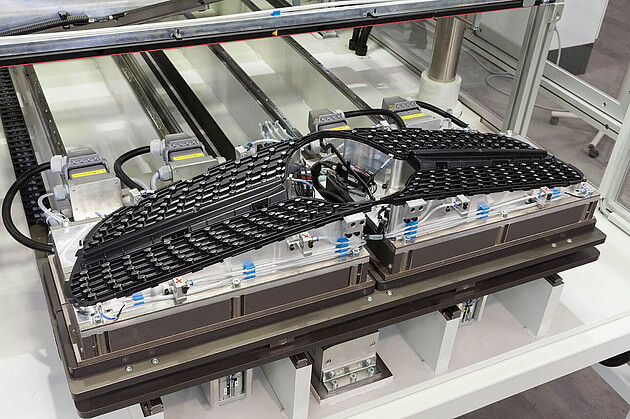

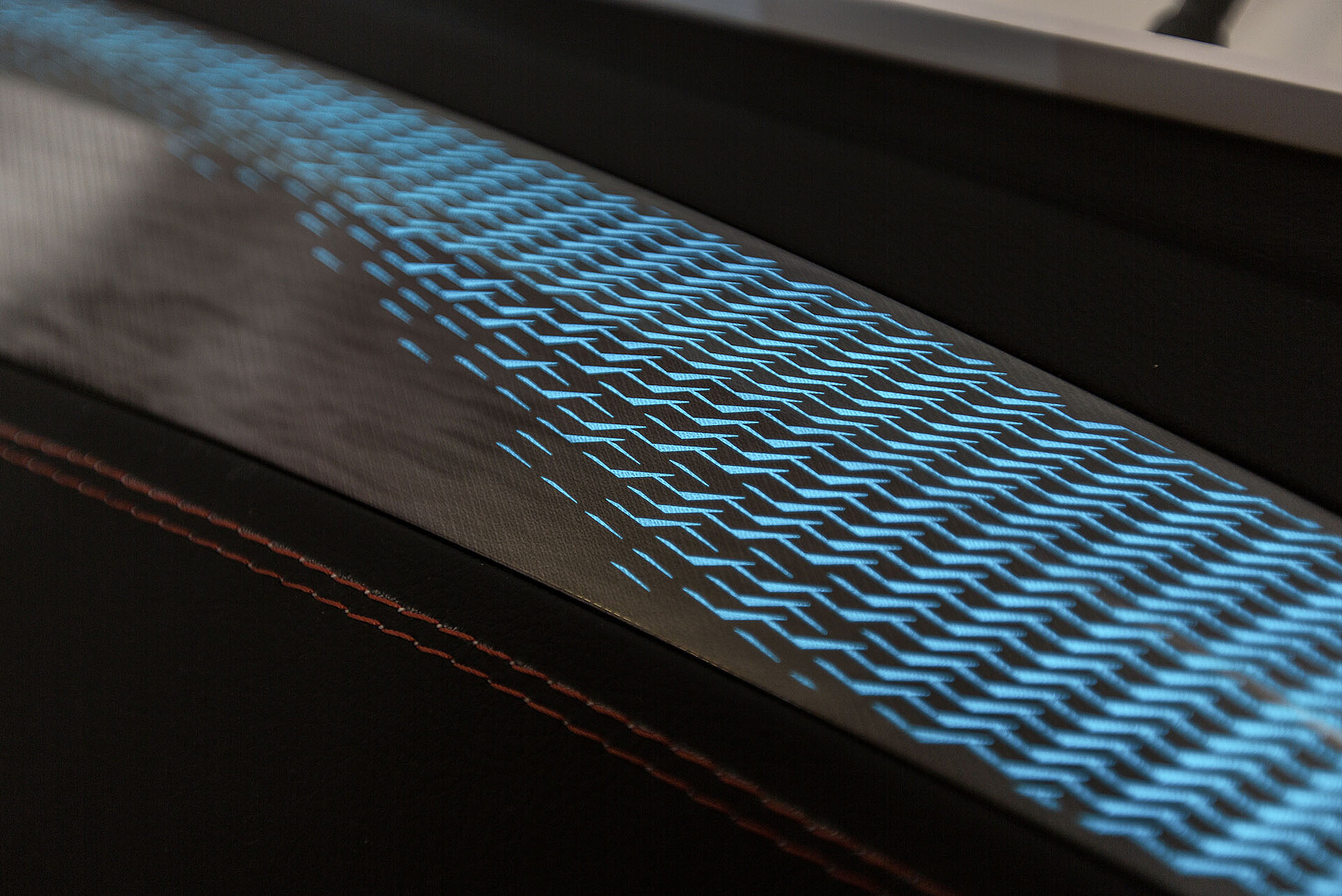

It’s the surfaces that make your products attractive. 75% of a product's appearance determines whether a customer is prepared to take a second look. KURZ's innovative In-Mold Decoration (IMD) process ensures that the surfaces of your products will attract customers as if by magic. With just one single step you will awaken their desires with special visual and haptic effects. But that’s not all: IMD can be combined with In-Mold Electronics (IME). For example, IME attaches transparent, conductive foils for touch sensors and decorative designs to the back of the component during injection molding. With this unique combination of two techniques, you can provide your surfaces with intelligence that is not obvious at first glance. We translate your visions into surprising surface designs, including functional touch controls.

Technology in a beautiful and attractive package

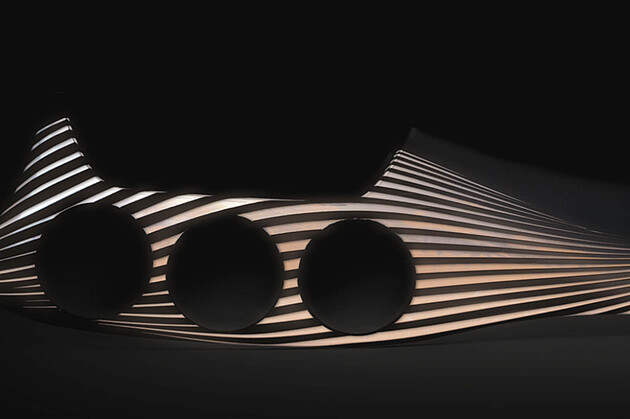

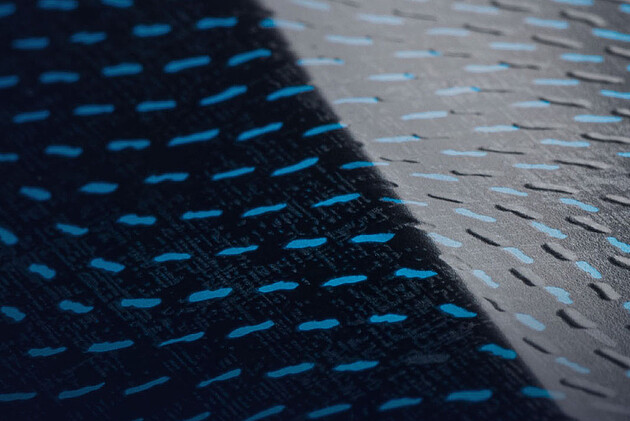

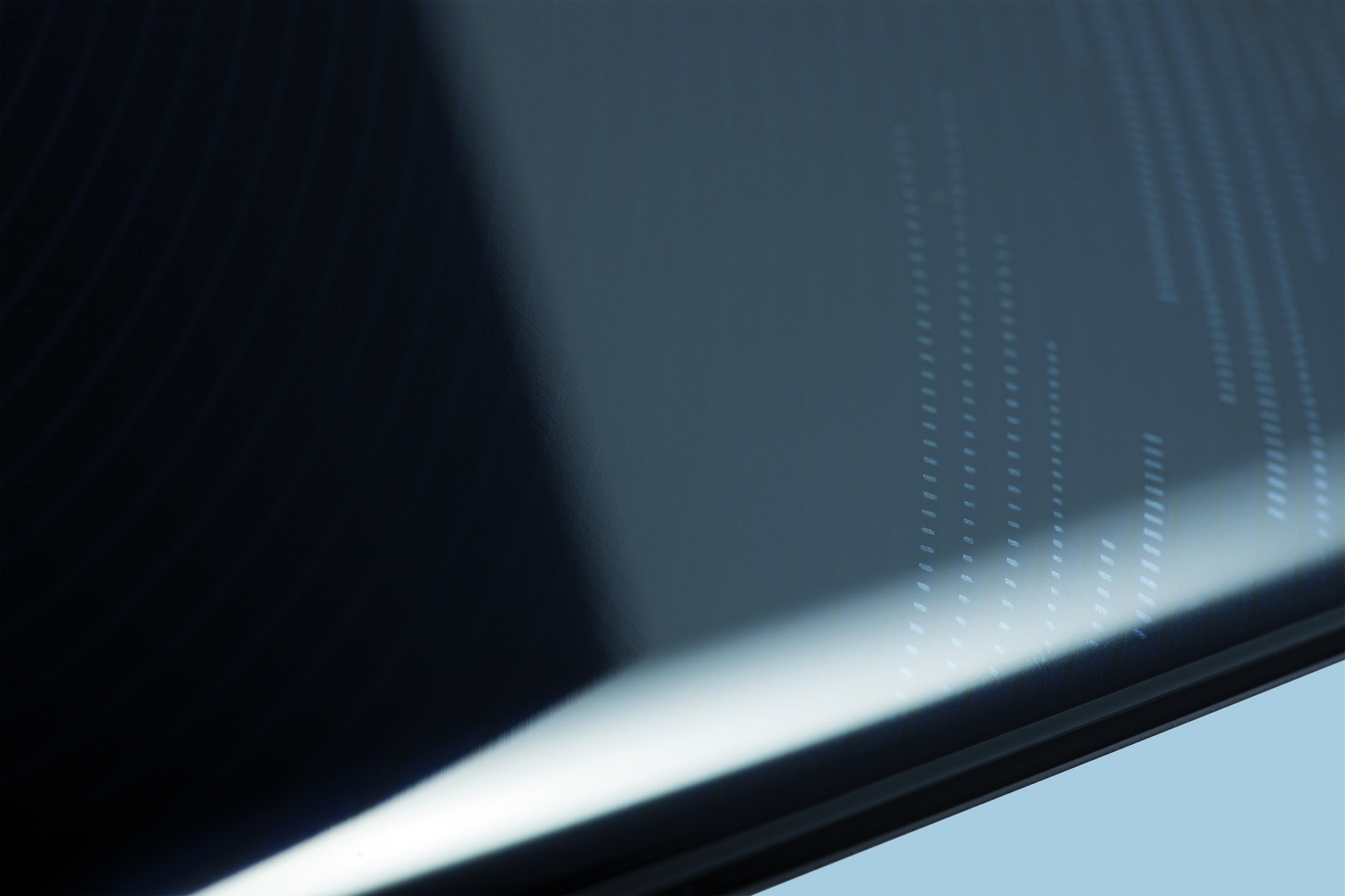

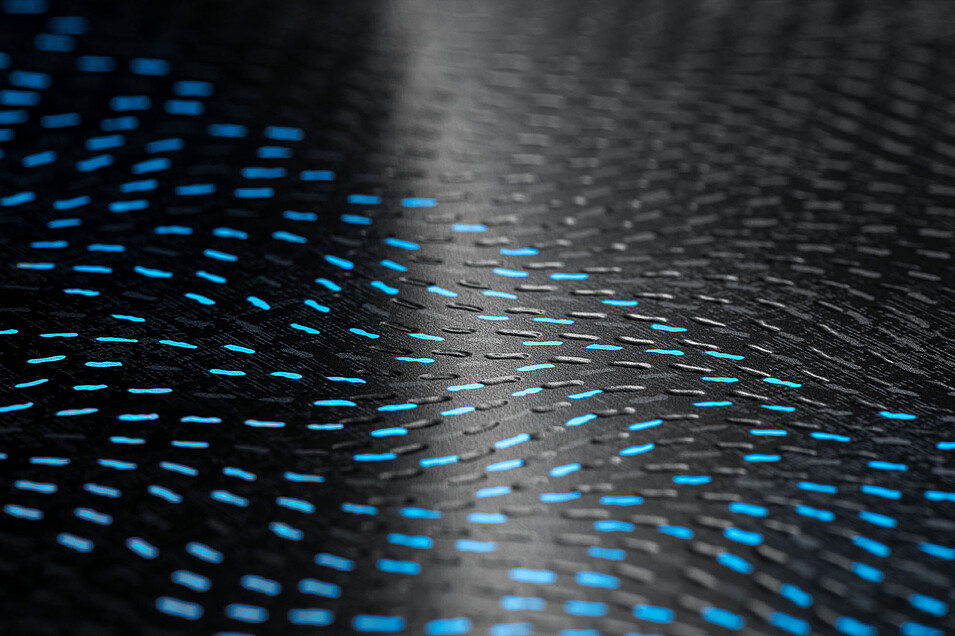

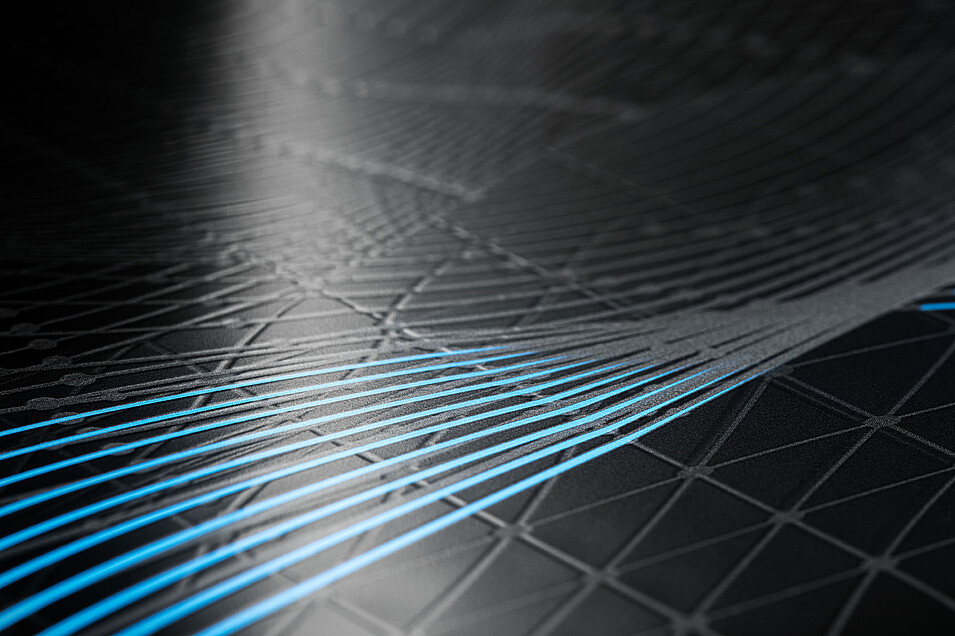

Smart home appliances with attractive surfaces and intuitive operation. Car steering wheels through which GPS, sound system, and ventilation can be reliably controlled - without distracting the driver. Metallic effects as an eye-catcher in a wide variety of colors and surfaces. Fascinating backlighting effects. In-Mold Decoration by KURZ makes all that possible. The process ensures that you get exactly the product you want in consistent quality and with your personal touch. And IMD gives you extreme freedom in design and feel, while protecting against external influences such as scratches, abrasion, sunscreen, and moisture. Offer your customers that certain something.

Reliable, consistent, efficient

With large volumes, in particular, it is not a given that the quality is right from the first to the last part. KURZ IMD solutions are designed so that you can always rely on the same quality. No shifted sensor, no indentation in the surface, or dull glow where the surface should shine.

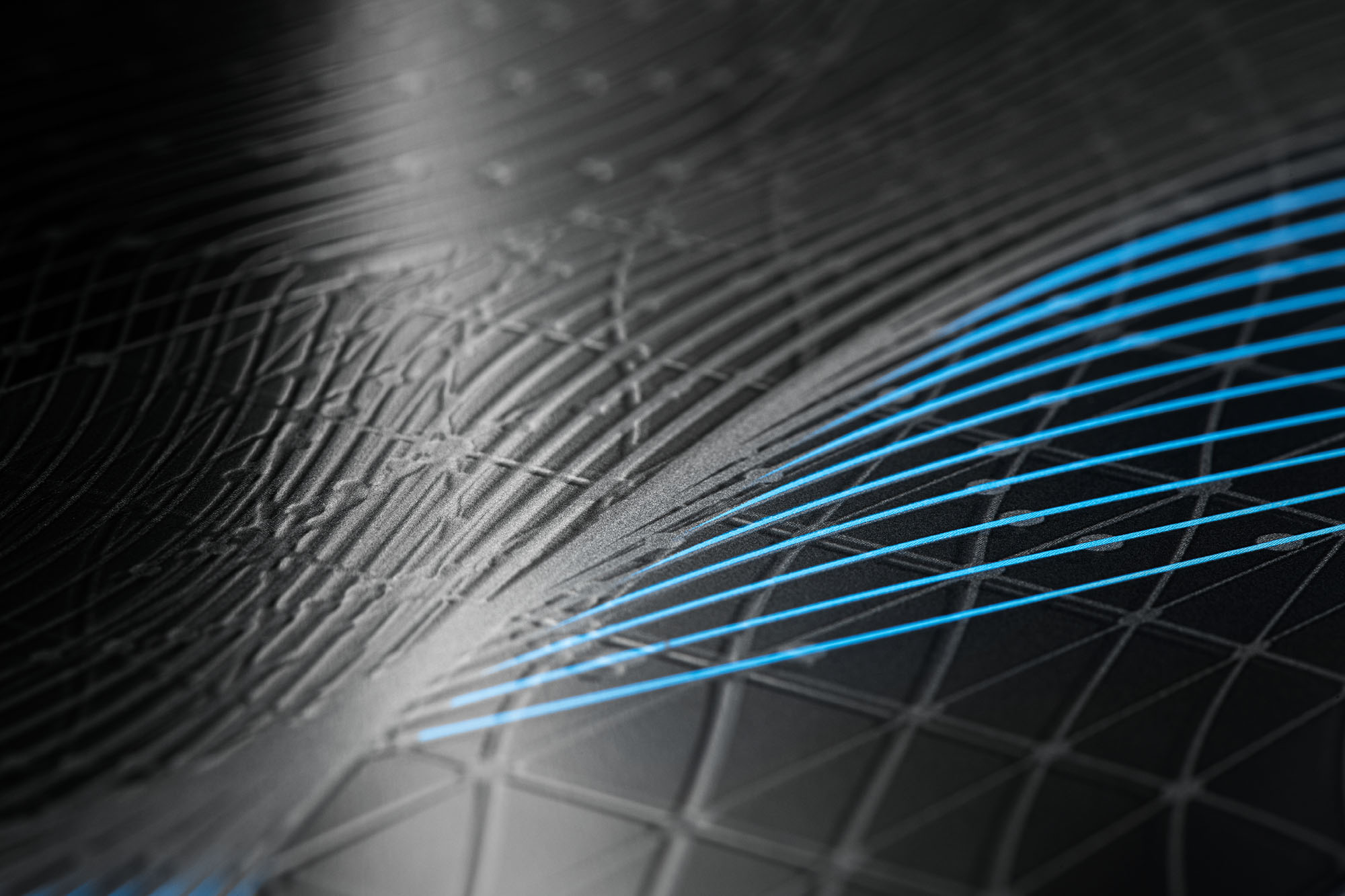

In order to set technological standards, KURZ is constantly advancing its processes. And that pays off: it’s how KURZ won the Automotive Brand Contest with its Cloudy Feathers Design. The design that was created using the IMD/IME process is a door trim with many functions as well as a special day and night feature. Another advantage of In-Mold Decoration: the process enables innovative surface designs that are not only aesthetic but also very robust. No wonder that notebook manufacturers often successfully work with IMD. With KURZ technology you can produce IMD decorations directly on site - for the benefit of the environment. KURZ is there wherever In-Mold Decoration is required.

Make your mark with IMD

Our aspiration is to make you shine. We offer you all our expertise, both in terms of technology and design: user-friendliness, maximum freedom of design, individual brand components, perfect symbiosis of design, lighting effects, and touch functions. Nothing more and nothing less.

The main advantages of KURZ In-Mold Decoration at a glance:

An eye-catcher for your customers. We identify trends and translate them into innovative design solutions - from brushed effects to marble designs, from high-gloss to ultra-matt, depending on which look it is you want

Economic integration into your value chain. Together with you, we select the machines and tools that are best for your purposes

Suitable for complex geometries, such as curved displays or 3D geometries

Various haptic effects can be achieved with soft-touch surfaces. This gives you an additional competitive advantage, as haptic design is increasingly becoming a distinguishing feature

Consistent quality, even for large volumes

Radiolucent, partial or full surface, day and night design, dead-front design, or ambient lighting

Metallized decors without shielding Wi-Fi, Bluetooth, or wireless connections. On request, we use non-shielding NCVM films (NCVM: Non-Conductive Vacuum Metallization).

We are constantly looking for ways to further improve our processes. In doing so, efficiency, innovation, and sustainability are just as important to us as your value chain. After all, our methods should fit in optimally with your processes. You’re looking for a reliable partner? Contact us!