News

Bewusst CO2 reduzieren

Verringern Sie Ihren CO2-Fußabdruck! Mit Conscious Concept bietet Ihnen KURZ eine Toolbox unterschiedlicher Maßnahmen.

NEU: Trends vol. 12

Aufbruch zu mehr Menschlichkeit: Entdecken Sie mit uns, wie sich ändernde Bedürfnisse und Einstellungen auf Designs auswirken. Erleben Sie, wie KURZ diesen Wandel in atemberaubende Kunststoffoberflächen übersetzt.

Visionary Design

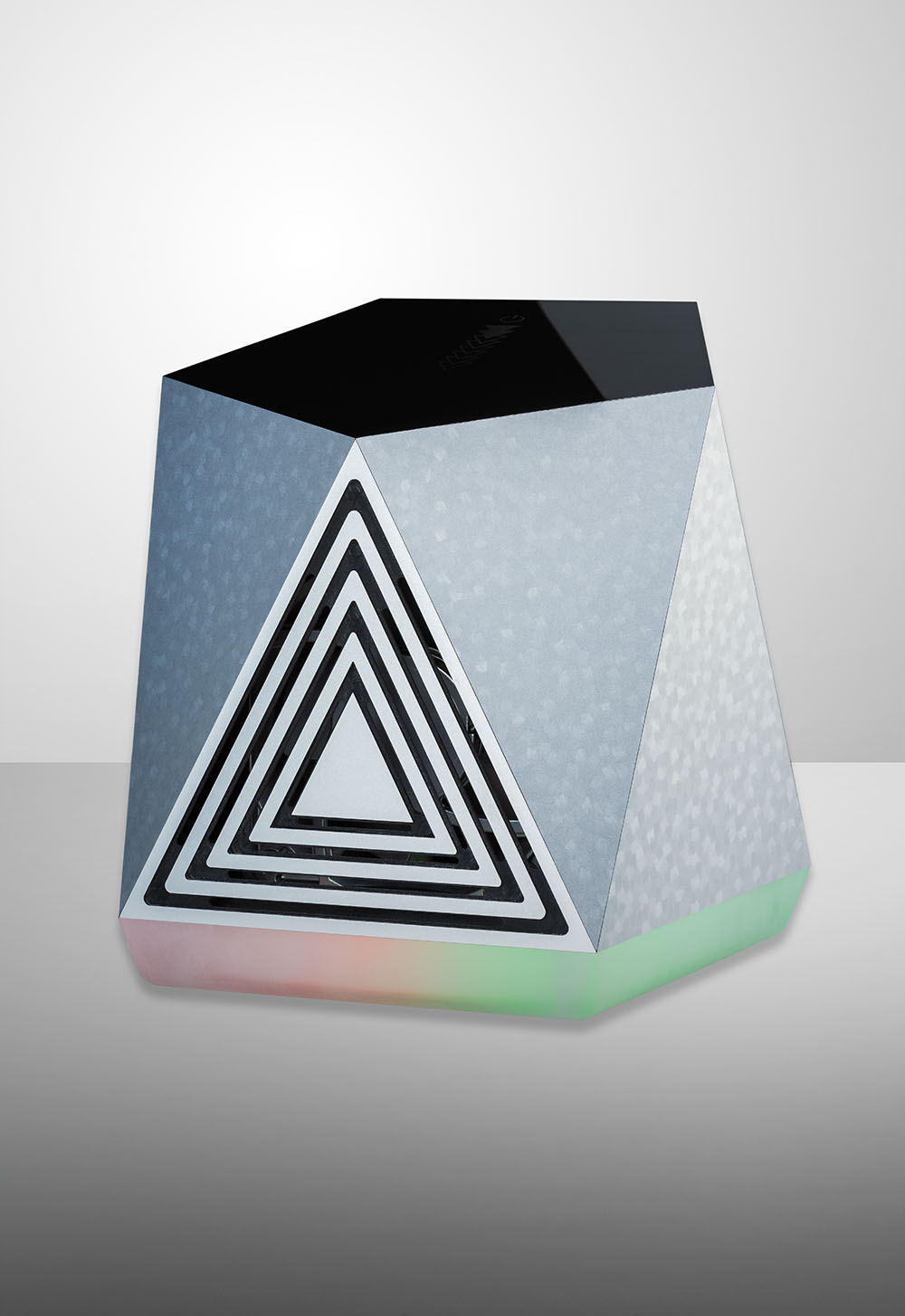

NEU: Spacewood Experiment

Entdecken Sie spektakuläre Inspirationen rund um das Thema holzähnliche Strukturen im Weltraum, die im ersten weltweiten Visionary Design Projekt entstanden sind. Aus 100% Post-Consumer und Post-Industrial Rezyklat. Holen Sie sich neue Impulse für Ihre Kunststoffoberflächen!

Design Check

KURZ Part Advisor

Mit dem KURZ Part Advisor finden Sie schnell die passende Dekoration für Ihre Bauteile. Denken Sie den Erfolg Ihres Projektes gleich von der ersten Sekunde an mit! Sie sind nur wenige Klicks von einer individuellen, effizienten und nachhaltigen Lösung entfernt.

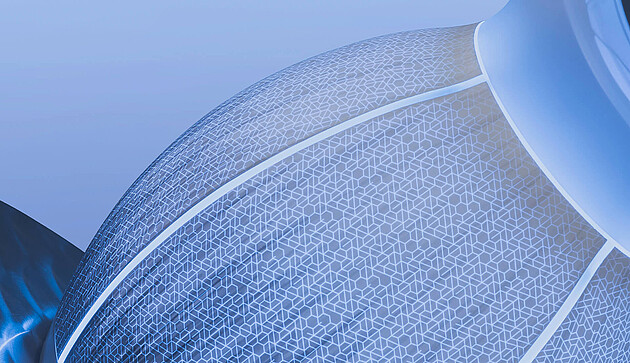

Kunststoffoberflächen von KURZ – ästhetische und technologische Meisterwerke

LEONHARD KURZ ist vom Konzept bis zur Serie Ihr globaler Design- und Servicepartner für die außergewöhnliche Oberflächenveredelung Ihrer Produkte. Für unsere überzeugenden Lösungen haben wir zahlreiche Auszeichnungen erhalten. Kreativität und Innovationsgeist sind fest in der KURZ-DNA verankert. Der Gründer Konrad Kurz legte den Grundstein für einen komplett neuen Industriezweig: Anfang der 1930er Jahre meldete er die allererste im Kathodenzerstäubungsverfahren mit Echtgold bedampfte Heißprägefolie zum Patent an. Damit machte er Blattgold, das bis dato in Handarbeit produziert wurde, für viele neue Einsatzmöglichkeiten zugänglich. Heute haben Sie die freie Auswahl: zahlreiche Oberflächenveredelungen für einfache oder komplexe Geometrien, prägend in Design und Technologie, für Einzelteile oder die Großserie. Jede neue Entwicklung ist für KURZ Interaktion zwischen Technologie, Design und Zukunft, mit einem besonderen Blick für den verantwortungsvollen Umgang mit unseren Ressourcen. Das Ergebnis: innovative Oberflächen, die neue Wege eröffnen und dabei heute schon die Ansprüche von morgen an Funktion und Design erfüllen. Überzeugen Sie sich selbst.

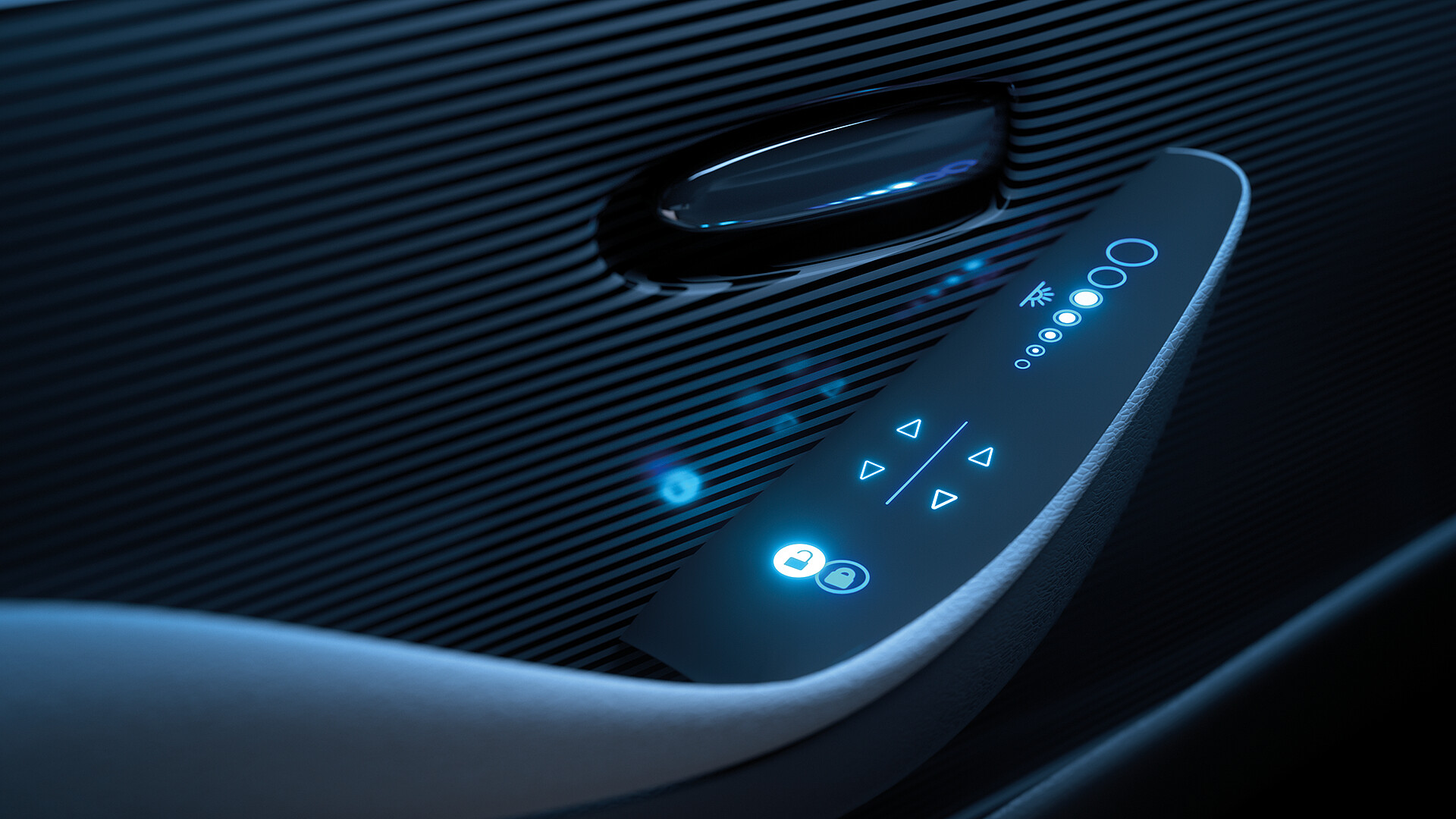

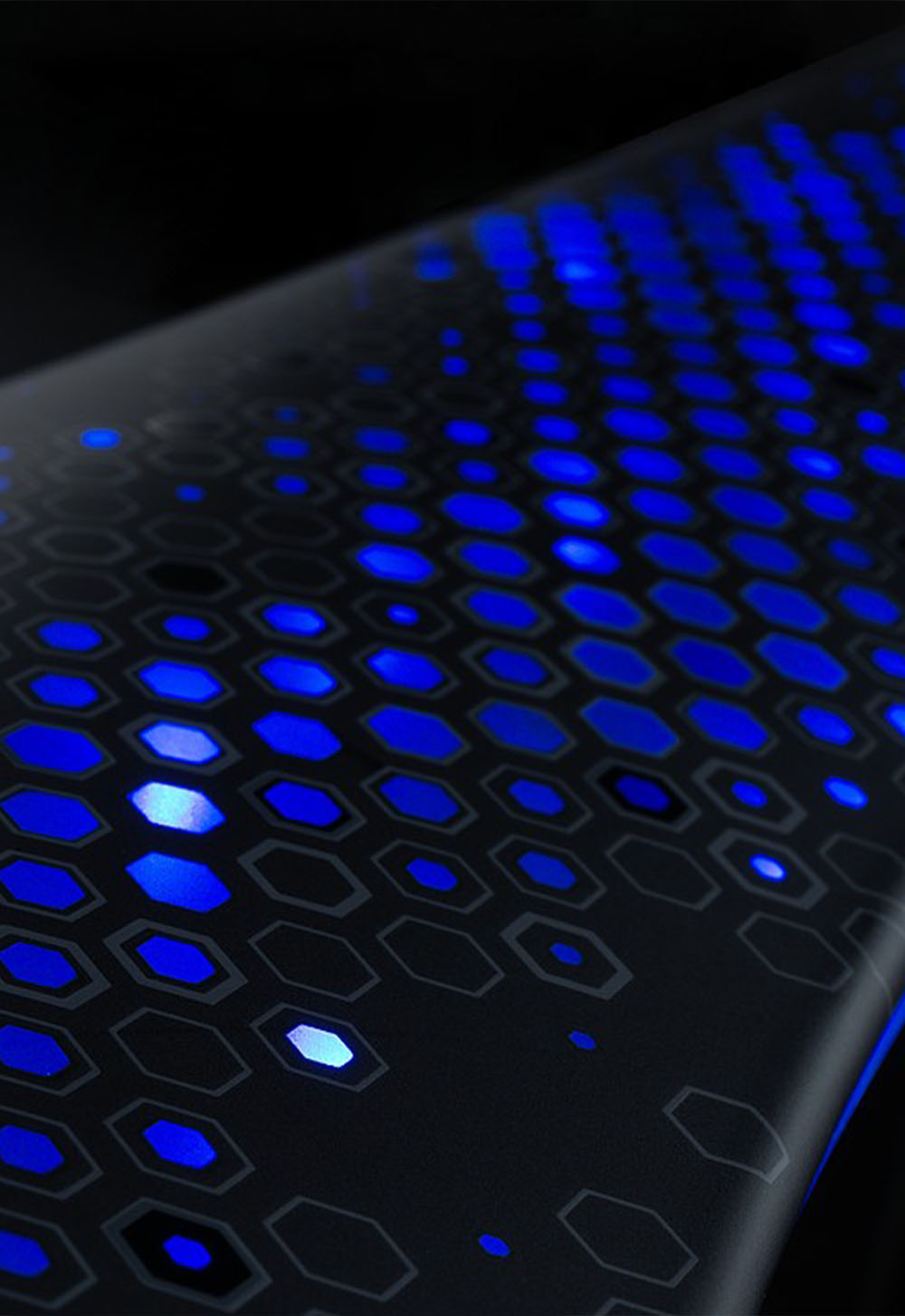

Branchenlösungen

Jede Branche hat ihre eigenen Ansprüche, was das perfekte Finishing angeht. Eines haben jedoch alle gemeinsam: Design und Funktionalität müssen überzeugen. Wir unterstützen Sie dabei, Kundenbedürfnisse schon im Voraus zu erahnen und passende Produkte zu entwickeln: smarte und intuitive Bedienoberflächen, Verpackungen als Attraktion am Point of Sale, widerstandsfähige und kratzfeste Veredelungen für Notebooks oder Haushaltselektronik, atemberaubende Hinterleuchtungseffekte und sinnliche Haptik. Wir haben die passende Lösung für Sie. Dabei streben wir danach, künftigen Generationen eine bessere Umwelt zu bieten. Wir denken in Lebenszyklen und entwickeln Dekorationen nach höchsten Standards für Mensch und Natur. So lassen sich mit KURZ-Dekoren auch Rezyklate ebenso hochwertig, individuell und ästhetisch veredeln wie Produkte aus neuen Materialien. Außerdem sind unsere Finishings recyclingfähig, denn sie sind dünner als ein menschliches Haar. Vertrauen Sie auf unsere umfassende Expertise in der nachhaltigen Oberflächenveredelung von Kunststoffen für die unterschiedlichsten Branchen. Ihr Nutzen: serienfähige, effiziente Lösungen, recyclingfähige Oberflächen und visionäre Designansätze mit maximaler Gestaltungsfreiheit. Verleihen Sie Ihrer Marke ein unverwechselbares Gesicht!

Visionary Design

Inspiration now begins

Um wirklich NEUES zu schaffen, braucht es ein deutlich formuliertes WARUM – eine klare innere Haltung, die den Kompass für neue Ideen, hoch innovative Ansätze und eben visionäre Designs bildet. Aus diesem Grund haben wir Visionary Design initiiert: eine unternehmenseigene Inspirationsquelle für Vordenker, Nachdenker und Weiterdenker – mit dem Ziel, kreative und neue Impulse in der Welt der Oberflächengestaltung zu schaffen und zu bieten.

KURZ

Making every product unique

Diesen Anspruch realisiert KURZ mit mehr als 5.500 Mitarbeitern an über 30 globalen Standorten. KURZ ist weltweit führend in der Oberflächenveredelung und produziert in Europa, Asien und den USA nach gleichen hohen Qualitäts- und Umweltstandards.

Newsletter

OROFIN – Das Online-Magazin von KURZ

Werfen Sie mit uns einen Blick in die Zukunft der Oberflächendekoration und erfahren Sie, was heute schon machbar ist. Freuen Sie sich auf Inspirationen und Ideen, spannende Geschichten und Innovationen aus der Welt von KURZ!

KURZ

TISAX-Zertifizierung

Transparenz, Kundenorientierung und die Einhaltung höchster Standards sind uns wichtig.