DECOPUR®: Coating with PUR (polyurethane)

Highlight for the automotive industry: perfect decoration with crystal clear PUR coating for injection molded parts

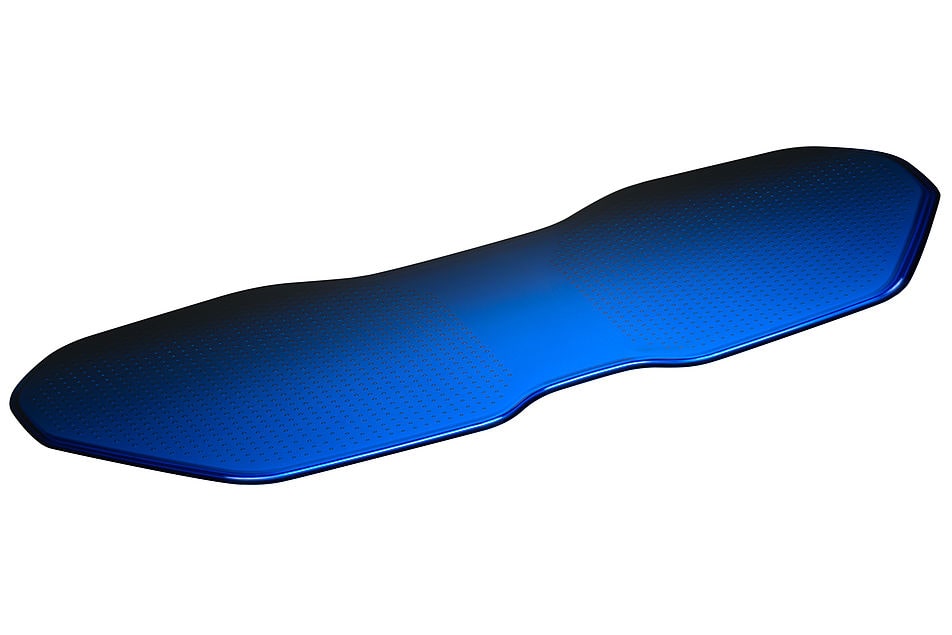

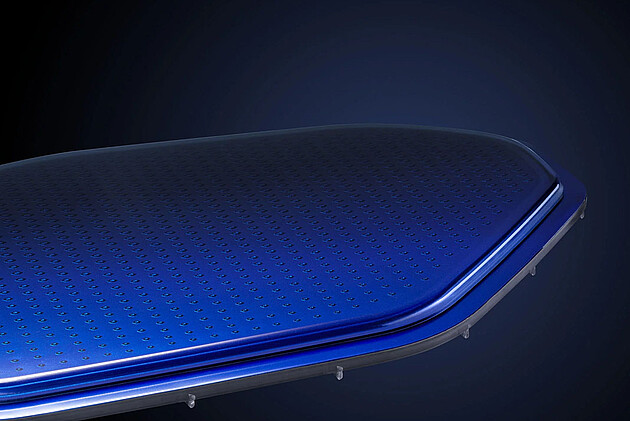

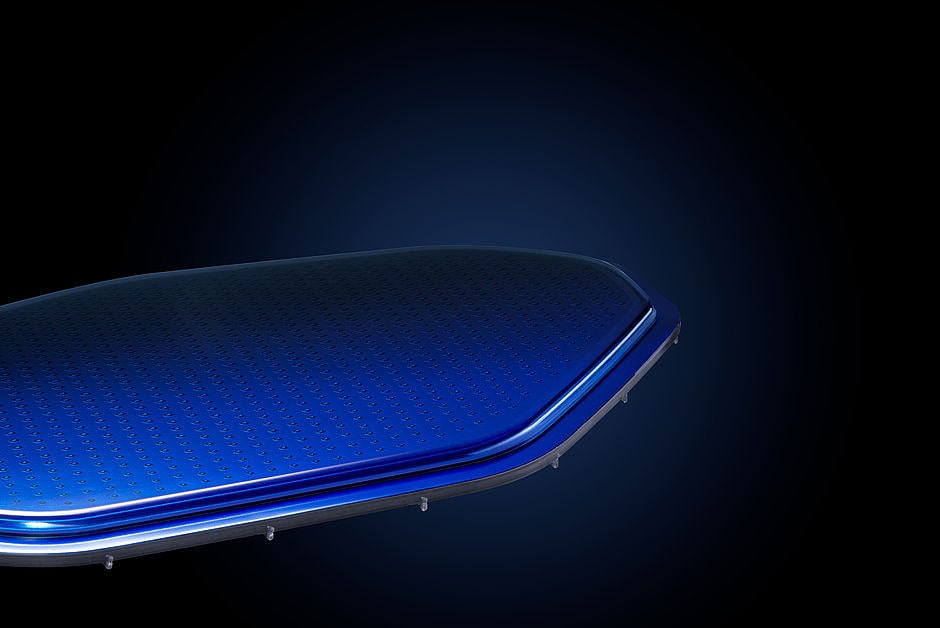

KURZ presents DECOPUR®, aworld first of groundbreaking significance for serial production in the automotive industry. This process forms front panels with intricate geometries right in the same machine clamping unit and then directly applies multiple decorations. In-Mold Decoration (IMD) applies premium designs to plastic surfaces. In the same manufacturing step, the entire component part can be flooded with polyurethane (PUR) to produce crystalline, high-gloss, and extremely durable surfaces. For the first time, all three manufacturing steps can be combined, forming an extremely strong bond between the three layers. This leads to highly efficient processes and groundbreaking new products that help manufacturers come up with even more complex product designs that can include functions for autonomous driving. In an era in which new aesthetic and functional demands drive developments in automotive engineering, KURZ can break entirely new ground together with you: with parts aligned for self-driving cars, integrated features for autonomous road user communication, front designs specific to e-vehicles, the merging of surface and light design, and extremely durable, self-healing exterior body materials.

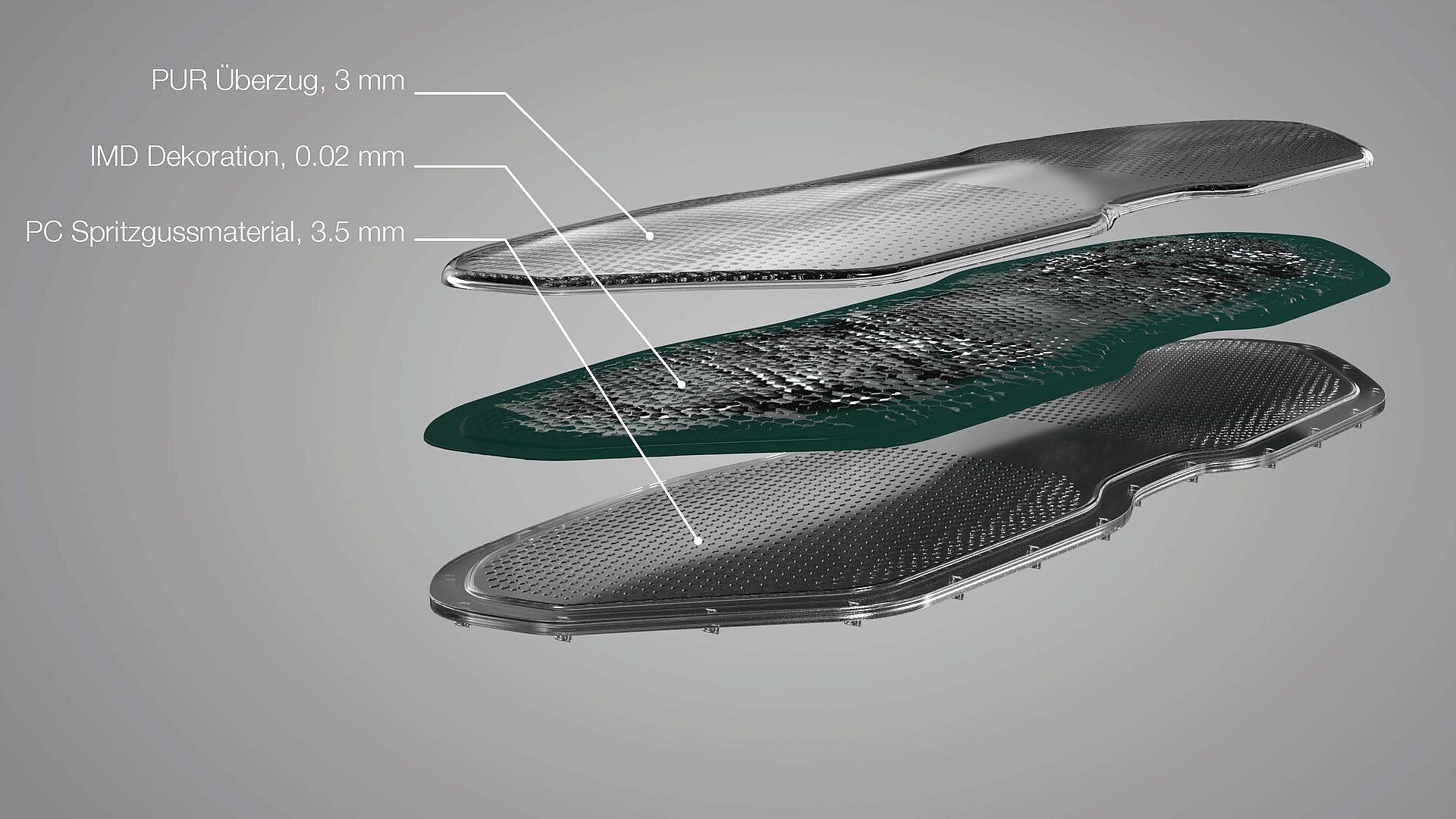

DECOPUR® – technical details at a glance

Development of the innovative DECOPUR® process came down to solving two major technical challenges: tying in the IMD decoration allows for optimal, highly durability adherence of all material layers involved. At the same time the tool technology, from injection molding to PUR topcoat application, had to be precisely adapted to the complex cycle of the clamping unit. KURZ teamed up with the skilled engineers at Schöfer, an innovative injection mold tool manufacturer who contributed its comprehensive know-how in thin-film and process technology. As part of the KURZ Group, the Schöfer company delivers technologically sophisticated special-purpose solutions for industrial plastics production.

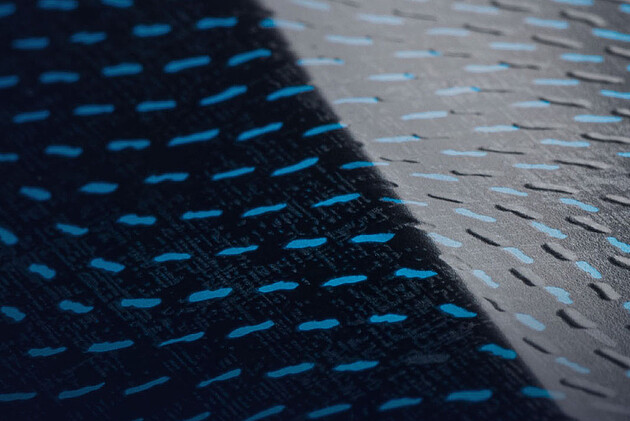

Together with the plastic compound and in the same injection molding process, the substrate bearing the motif is pressed directly into the wall of the machine cavity

At the set temperature in the machine, the wafer-thin decorative substrate coating dissolves and forms an extremely strong bondwith the plastic surface

In the next step in the same machine pass, the piece is flooded with polyurethane (PUR)

This creates injection molded parts and components boasting premium designs under a crystal-clear PUR surface

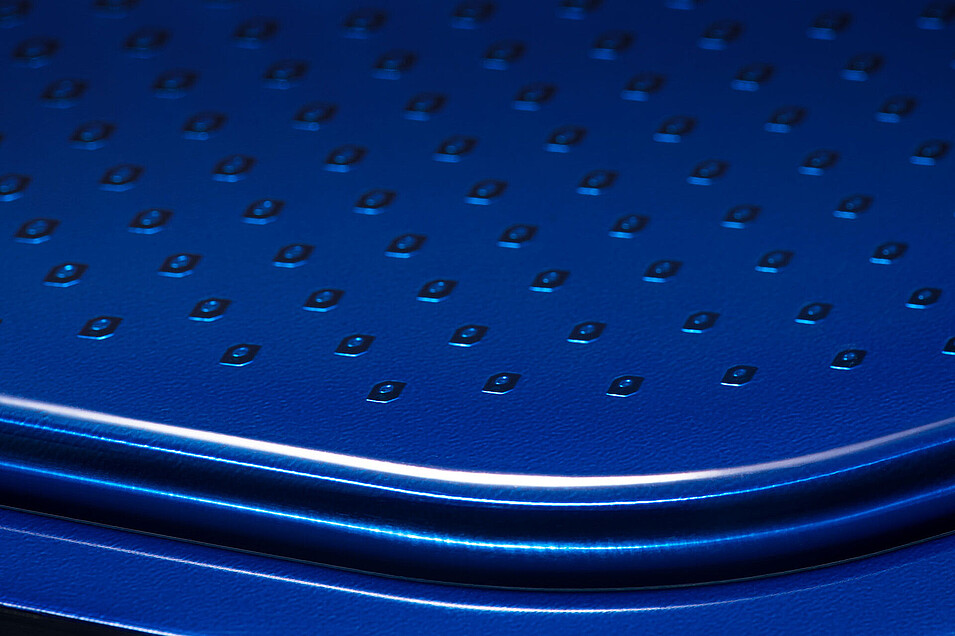

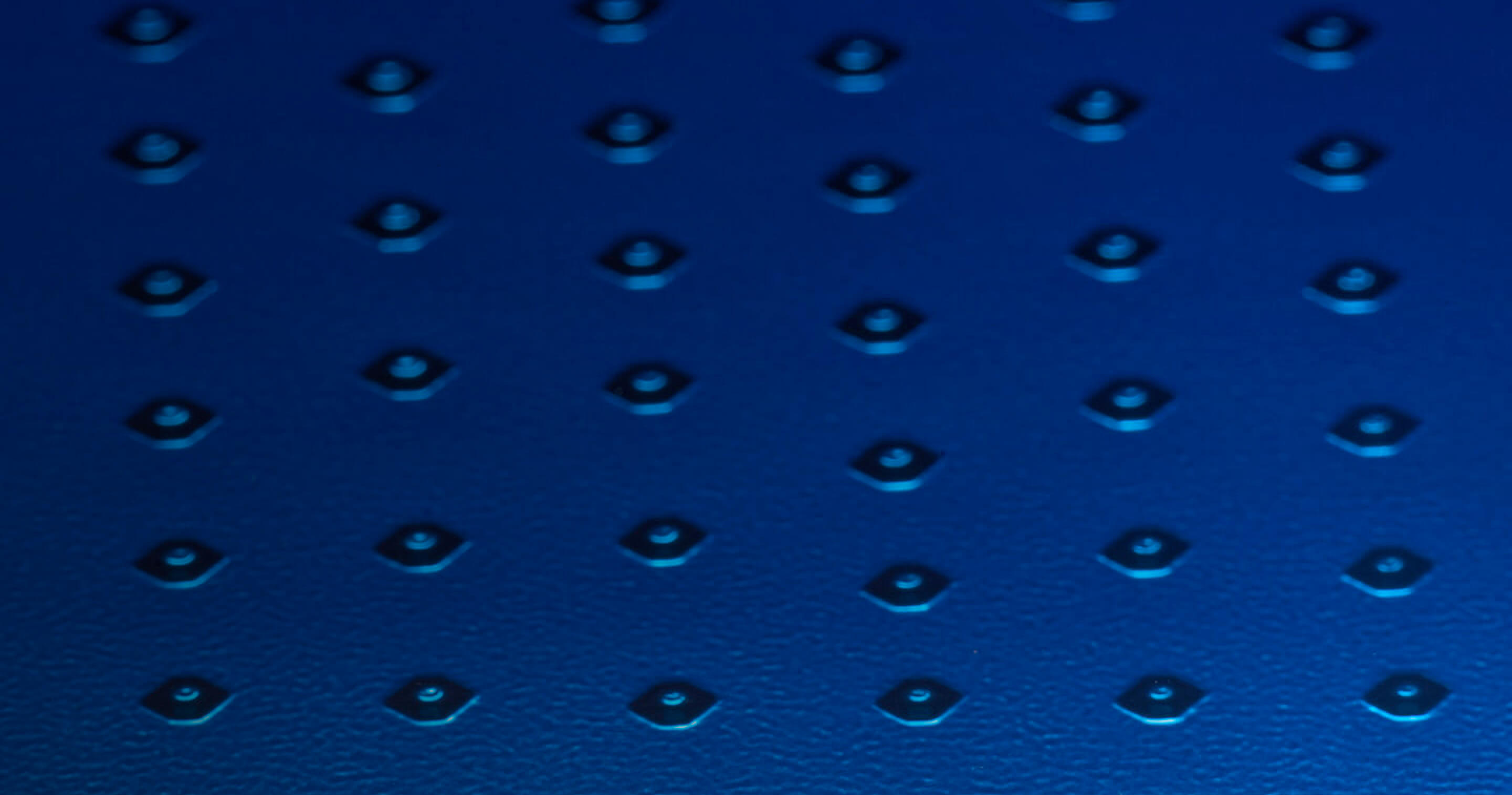

The crystalline, high gloss finish dramatically showcases the colors, lines, patterns, and structures of the decoration. In particular, this innovative technology delivers unrivaled 3D effects. The decoration acquires an unprecedented plasticity and breathtaking depth effect

Because surfaces are completely coated with PUR, they boast self-healing features in case they are scratched, cracked or damaged

Designs – seamless orientation toward the future of autonomous driving and e-mobility

Self-driving vehicles require materials that can be penetrated by LiDAR and radar beams. Moreover, the corresponding components on the vehicle exterior must possess enormous physical stability.

Polyurethane makes a smart impression – and provides real protection

The transparent luster of PUR surfaces comes with the reliable sealing and high protection furnished by the integrated decoration. If you, for instance, manufacture parts for automobile exteriors, colors and aesthetic design are protected against chipping and scratches. To a certain extent, PUR topcoats feature a self-healing reaction to scratches. Slight heating of the material, for instance by sun radiation, usually suffices to level and smooth scratches. In this feature as well, there lies important ecological benefits. Radiator grilles and other vehicle components made of especially durable plastic help avoid waste. You save maintenance and service expense. So, they are not only pleasing to the eye, but also sustainable and thereby ideally suited to positioning you even better vis-a-vis competitors. Consider the many other appealing features, including high stability to light and UV radiation, outstanding abrasion hardness, and reliable resistance to corrosion, especially from moisture and rapidly fluctuating temperatures.

KURZ delivers a one-stop solution from a single source

Are high quality injection-molded components sporting the finest decoration under crystal-clear PUR causing a sensation among your clients? You can directly implement these innovations. KURZ provides you with all services and materials needed for a one-stop solution for your serial production. Talk to us about KURZ providing technical consulting directly at your facility. We look forward to hearing from you and can plan the entire solution from A to Z. In addition to a powerful injection molding machine, this requires premium DECOPUR® and decoration materials from KURZ. We use IMD and PUR coatings in fine-tuned alignment to provide top technical security, together with matching process-optimized tools for significantly shorter cycle times and greater efficiency in your value creation.